How Do Shipping Label Printers Work? A Clear Breakdown

11th Jul 2025

Printing shipping labels shouldn’t feel like a daily struggle. But for many small businesses, it often does. Whether it's smudged prints, wasted labels, or compatibility issues with carriers like UPS or FedEx, these frustrations slow down fulfillment and hurt customer satisfaction.

That’s why understanding how shipping label printers work can make all the difference. This blog breaks down the process in simple terms: what these printers do, how thermal printing works, and how to choose the right one for your needs. By the end, you’ll know exactly how to streamline your shipping process with the right tools from OmegaBrand Sales Corporation.

What Are Shipping Labels?

Shipping labels are essential documents that accompany packages during transit. They provide vital information, including the sender's and recipient's addresses, tracking numbers, and barcodes. Accurate shipping labels ensure efficient handling and delivery by carriers while minimizing delays in the shipping process.

They help identify where the package is going, which carrier handles it, and how it should be processed. Each shipping label, such as the LabelJET Direct Thermal 4"x6", includes key details like routing codes and service level. This ensures that automated sorting systems can process and deliver packages accurately. Improper or missing labels can result in delays, misroutes, or even lost shipments. That's why choosing the correct label format and printing method is as important as the shipping service.

How Shipping Label Printers Operate?

Thermal printers utilize heat to transfer ink from a ribbon onto shipping labels or directly onto thermal paper. They operate quickly and efficiently, producing clear, smudge-proof labels. This method is popular for high-volume shipping due to its cost-effectiveness and minimal maintenance requirements.

Shipping label printers, particularly thermal printers, use a precise heat-based process to produce clear, durable labels quickly and efficiently. Here’s how they function technically to print labels:

-

Step 1: Feeding the Label Material

The printer pulls a roll or stack of specially coated thermal label paper or label stock through its print mechanism. -

Step 2: Thermal Print Head Activation

A thermal print head containing tiny heating elements moves across the label surface. Each element heats up individually based on the printed image or barcode data. -

Step 3: Creating the Image

In direct thermal printing, the heat activates a chemical reaction on the heat-sensitive label paper, turning those areas black to form the text, barcode, or graphics. -

Step 4: Drying and Curing

Since the printing process uses heat rather than liquid ink, the label dries instantly, eliminating smudging or drying time. -

Step 5: Advancing the Label

The printed label moves forward to the output area or cutter, ready to be applied to packages or shipping cartons.

This precise thermal printing process ensures labels are sharp, durable, and ready for fast scanning during shipping and delivery.

What Are the Details Mentioned on a Shipping Label?

Shipping label printers are designed to create durable, scannable labels that carry key delivery details. The most commonly used type, thermal printers, offer a fast, efficient, and ink-free solution for printing shipping labels.

Thermal printers work by applying heat to specially coated label paper. There are two types:

-

Direct Thermal (DT): Uses heat-sensitive paper that darkens when heated. This method is ideal for short-term use, such as shipping labels, though the prints may fade over time when exposed to heat or sunlight.

-

Thermal Transfer (TT): Uses a ribbon coated with wax or resin. Heat transfers the ribbon's ink onto the label, resulting in long-lasting prints suitable for storage or exposure to harsh environments.

Unlike traditional inkjet or laser printers, thermal printers do not require ink or toner. This reduces maintenance costs and eliminates smudging. Most thermal label printers support 4x6 labels, the standard size accepted by major carriers like UPS, FedEx, and USPS.

Their compact design, fast printing speeds, and ability to handle high-volume label printing make thermal printers a practical choice for retail, e-commerce, logistics, and warehouse operations.

How to Create Shipping Labels?

Creating accurate and scannable shipping labels ensures packages reach their destination without delays or mix-ups. Whether you’re a small business owner or managing a large e-commerce operation, a proper label helps carriers identify, sort, and deliver your parcel efficiently. Here's a step-by-step breakdown to get your labels right every time.

1. Start with Your Carrier’s Website

Major shipping carriers like UPS, FedEx, USPS, and DHL offer built-in website tools to generate shipping labels. You’ll enter details like sender and recipient addresses, package dimensions, weight, and preferred shipping speed. These portals also let you schedule pickups, track packages, and pay for postage online.

2. Grab a Free Shipping Label Template

If you're creating labels manually or using software, free shipping templates can help you format everything correctly. These templates usually follow standard dimensions (4x6 inches) and include sections for barcodes, addresses, and service levels. A well-structured template ensures consistency and avoids missing critical fields.

3. Use a Shipping Tool to Save Time

Shipping software platforms like ShipStation, Pirate Ship, or EasyPost streamline the process by integrating directly with major e-commerce platforms such as Shopify, WooCommerce, BigCommerce, Magento, and Wix. These tools can automatically import order details, auto-fill label data, compare shipping rates across carriers, and even batch-print labels in bulk. This saves you time, reduces manual entry, and helps avoid costly errors, especially during high-volume order periods.

4. Don’t Skip the Important Details

Even a small mistake on a label can result in lost or returned packages. Make sure to include:

-

Full sender and recipient addresses

-

Valid tracking number

-

Proper postage paid

-

Barcode (scannable and printed)

-

Shipping method or service selected

Double-check spelling, ZIP codes, and ensure the weight and dimensions match the actual package.

5. Stick the Label Right — And Tight

A shipping label must be firmly attached and fully visible on a flat surface. Avoid placing it over seams, edges, or tape. For thermal labels, make sure the adhesive is strong and the print is dark and smudge-free. If printing on plain paper, use a label pouch or cover it with clear tape — but never tape over barcodes, as it may interfere with scanning.

How To Print Thermal Shipping Labels?

Printing thermal shipping labels is a straightforward process that removes the need for ink or toner. These printers use heat-sensitive labels and are ideal for high-speed, high-volume shipping environments. Here's how the process works and what you'll need to get started:

1. Choose the Right Thermal Printer

There are two types: direct thermal and thermal transfer. Direct thermal printers are widely used for shipping labels because they're cost-effective and perfect for short-term labeling. Models like the Godex DT4xW, Brother TD4210D, and Toshiba BV410D are popular for 4x6 shipping label formats.

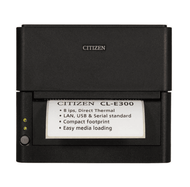

Check out the Citizen CL-E300XUBNNA for fast, space-saving shipping label printing.

2. Use Compatible Label Rolls

Thermal printers require specially coated, heat-sensitive label rolls. Most shipping carriers—including UPS, FedEx, USPS, Amazon, and eBay—accept standard 4x6-inch labels, which these printers are designed to handle.

3. Install Printer Software or Drivers

Most thermal printers come with driver software that supports both Windows and Mac. Installation typically involves connecting the printer via USB, LAN, or Wi-Fi and configuring print settings to match label size and layout.

4. Generate Shipping Labels from Your Platform

Whether you’re shipping through a carrier website or an e-commerce platform like Shopify, Etsy, eBay, or Wix, you can generate shipping labels directly or through integrated apps like Shippo, ShipStation, or Easyship.

5. Load the Labels and Print

Once your label file (usually in PDF or ZPL format) is ready, load your labels into the thermal printer, align them correctly, and print with one click. These printers offer fast, smudge-free output—ideal for busy shipping desks.

Using thermal shipping label printers ensures efficiency, accuracy, and a clean, professional appearance that builds customer trust and reduces package handling issues.

Best Thermal Shipping Label Printers to Choose

Choosing the right thermal printer makes a big difference if you want to streamline your shipping process. Below are some top-performing models trusted by businesses of all sizes. Each one offers unique features that suit different shipping needs.

1. Godex DT4xW Shipping Label Printer Package

The Godex DT4xW is a direct thermal label printer for fast and reliable shipping tasks. It delivers efficiency and durability, making it a favourite for growing businesses.

Key Features:

-

Print Method: Direct Thermal

-

Resolution: 203 dpi

-

Print Speed: Up to 7 inches per second

-

Connectivity: USB 2.0 and Ethernet

-

Max Label Width: 4.25 inches

-

Build Quality: Compact and sturdy with a fanfold label slot

-

Warranty: 3-year limited warranty

Best for: Medium to large-sized businesses requiring fast, high-volume label printing with network support.

Advantages:

-

Durable, rugged construction designed for demanding environments

-

Network-ready with USB and LAN support for seamless integration

-

Capable of high-volume label printing with minimal interruptions

-

Features user-friendly media loading for operational efficiency

-

An extended 3-year limited warranty underscores reliability.

Limitations:

-

Larger physical size could be restrictive in tight spaces.

-

Printing speed is competitive but not the fastest (7 inches per second)

-

The initial cost is higher compared to entry-level models.

2. Brother TD4210D Shipping Label Printer

Built for performance and simplicity, the Brother TD4210D is ideal for businesses that want to balance power and ease of use.

Key Features:

-

Print Method: Direct Thermal

-

Resolution: 203 dpi

-

Print Speed: 5 inches per second

-

Connectivity: USB and Serial interfaces

-

Media Handling: Supports rolls up to 5" in diameter

-

Build Quality: Compact and durable with a sleek design

-

Warranty: 2-year Premier Limited Warranty

Best for: Small to medium businesses needing a cost-effective, daily-use label printer with consistent output.

Advantages:

-

Delivers dependable and steady direct thermal printing performance

-

Space-efficient, making it suitable for environments with limited room

-

Compatible with both Windows and Mac operating systems for broad usability

-

Supports label rolls up to 5 inches in diameter, accommodating various needs

-

Requires minimal maintenance, reducing downtime

-

Comes with a reassuring 2-year Premier Warranty

-

Seamlessly integrates with popular shipping software.

Limitations:

-

Print speed maxes out at 5 inches per second, slower than some competitors.

-

Connectivity options are limited to USB and Serial; no network capabilit.y

-

Best suited for low to moderate shipping volumes; may struggle with heavy demands

3. Toshiba BV410D-R Shipping Label Printer Package

The Toshiba BV410D-R offers high-speed printing, sharp resolution, and built-in durability. It combines advanced features with a space-saving design, perfect for busy shipping environments.

Key Features:

-

Print Method: Direct Thermal

-

Resolution: 203 dpi

-

Print Speed: Up to 7 inches per second

-

Connectivity: USB 2.0 and LAN (Ethernet)

-

Additional Features: LCD, internal rewinder option, easy maintenance design

-

Build Quality: Strong industrial-grade construction in a compact footprint

-

Warranty: 1-year standard warranty

Best for: High-volume operations that need a fast, intuitive printer with added user controls and connectivity options.

Advantages:

-

Combining rapid print speeds of up to 7 inches per second with high precision

-

Features an LCD panel for easy monitoring of printer status

-

Equipped with auto-calibration and self-diagnostic capabilities to lower maintenance needs

-

Compact and sturdy with top-loading media for convenience

-

Designed to handle rigorous, high-volume printing tasks

-

Connectivity via USB and LAN enhances integration flexibility

Limitations:

-

Warranty coverage is limited to 1 year

-

Advanced features may come at a higher price point

-

User interface complexity might require some initial training

Best Practices for Label Placement on Packages

Correct label placement is as essential as having a quality shipping label printer. Misplaced or unreadable labels can cause delays, returns, or even lost packages. OmegaBrand Sales Corporation provides high-quality shipping label printers and helps businesses follow industry-best labelling practices for efficient deliveries.

Know Your Shipping Needs Before You Start

Before printing or applying any labels, it's essential to assess your shipping needs based on:

-

Package size and material – A small poly mailer needs different label positioning compared to a large corrugated box.

-

UPS, FedEx, and USPS have specific label placement instructions for shipping destination and carrier guidelines.

-

Label type compatibility – Use durable, smudge-free thermal labels that suit your printer (e.g., direct thermal labels for Godex DT4xW or Toshiba BV410D-R).

-

Environmental considerations – If your packages are exposed to heat, moisture, or friction, you may need water-resistant or fade-proof labels like the ones supported by Citizen or Toshiba models from OmegaBrand.

Set Yourself Up with the Right Carrier & Capital

Getting your label placement right also depends on the tools and carriers you choose:

-

Partner with reliable carriers like FedEx, USPS, UPS, or DHL, which offer online tools and templates to help standardize label format and layout.

-

Invest in compatible shipping software that works seamlessly with OmegaBrand's thermal printers for automatic formatting.

-

Use the correct label size (commonly 4x6 inches) and apply it to the largest flat surface, avoiding seams or edges.

-

Smooth application is key – OmegaBrand recommends using label applicators for high-volume shipping to ensure wrinkle-free, properly aligned placement every time.

With a professional-grade printer and label placement strategy, you improve scan accuracy, reduce return rates, and speed up your fulfilment process. OmegaBrand's support doesn't end with hardware — we help you label smarter from print to placement.

Conclusion

Adapting efficient label printing ensures professional presentation, cost savings, and smoother logistics. Quality thermal printers like Godex DT4xW, Brother TD4210D, and Toshiba BV410D help streamline shipping, reduce errors, and save time. These reliable printers support diverse labeling needs and enhance operational flexibility. Combining them with proper label creation and placement maximizes resource use. Focusing on these details boosts your eCommerce business's efficiency and strengthens its reputation for excellence.

Frequently Asked Questions

Can shipping label printers handle different label sizes?

Yes, most thermal shipping label printers support a variety of label sizes. The 4x6 and 4x8 inch formats are the most commonly used for shipping, but all the printers mentioned above — including models like the Godex DT4xW, Toshiba BV410D-R, and Brother TD4210D — can also handle smaller label sizes based on your packaging needs.

Are there wireless shipping label printers available?

Absolutely. Wireless connectivity makes setup and printing more convenient. For example, the Godex DT4xW and Brother TD4210D desktop printers offer optional Wi-Fi or Bluetooth modules, allowing seamless printing from your laptop, phone, or tablet without tangled cords or complex wiring.

How often should a shipping label printer be serviced?

Thermal shipping label printers are designed for durability, but regular maintenance is still important. It's recommended to clean the printhead and internal components every time you change a label roll or ribbon. For high-volume usage, schedule a detailed service check every 3–6 months to ensure consistent performance and extend the printer’s lifespan.

What are the costs involved in operating a shipping label printer?

Operating costs for direct thermal shipping printers are typically low since they don’t require ink or toner. Your main expenses will include label rolls and occasional printhead replacements. For example, 4-inch wide direct thermal labels, the standard in shipping, are affordable and widely available through OmegaBrand. Since OmegaBrand is no longer selling Epson ColorWorks printers, and shipping labels are generally printed using thermal printers, choosing the right 4-inch direct thermal printer can help reduce ongoing costs and improve efficiency.