Bakery Label Printer Guide: SLP-721 and Labeling Tips

22nd Oct 2025

Key Highlights

-

Bakery labels play a key role in maintaining freshness, food safety, and brand consistency.

-

The SLP-721 stands out for its precision, rapid printing speed, and reliability in bakery environments.

-

Choosing the right materials and adhesives ensures labels stay intact on warm, cold, or greasy packaging.

-

Clear, well-designed labels improve readability, highlight product info, and strengthen brand image.

-

Compliance with allergen, ingredient, and nutrition labeling laws protects customers and builds trust.

-

Efficient label printing workflows save time, reduce waste, and improve accuracy in daily operations.

-

High-quality label printing helps bakeries of all sizes deliver professional, food-safe packaging that reflects their craftsmanship.

Running a bakery means juggling more than recipes. Between early-morning prep, fast-moving orders, and shelves full of tempting treats, labeling often becomes an afterthought. Smudged expiration dates, unclear allergens, or uneven branding can quickly turn beautiful packaging into confusion and even hurt customer trust.

That’s where a reliable bakery label printer makes a difference. The right printer keeps your labels clear, consistent, and food-safe, whether you’re tagging freshness dates, listing ingredients, or showcasing your logo. It’s not just about printing; it’s about saving time, staying compliant, and presenting your products at their best.

In this guide, you’ll discover how SLP-721 stands out, explore label types and materials, and learn smart design and workflow tips. We’ll also cover key compliance rules so every label you print looks professional, meets food safety standards, and strengthens your brand identity.

Why Are Bakery Labels Important, and What Makes Them Unique?

Walk into any bakery and you’ll notice something beyond the smell of fresh bread: labels everywhere. From “baked this morning” stickers to allergen alerts and brand tags, they quietly do the heavy lifting behind every product display.

Bakery labels aren’t just for looks or legal compliance. They also serve other purposes like:

-

Build trust by being transparent about ingredients, allergens, and freshness.

-

Reinforce your brand with consistent colors, fonts, and logo placement.

-

Improve efficiency by keeping inventory, pricing, and production organized.

However, bakery labels face challenges that most others don’t. They have to:

-

Withstand tough conditions like heat, grease, and humidity.

-

Stay clear and legible in refrigerated or display cases.

-

Adhere reliably on paper boxes, plastic wraps, and uneven surfaces.

The combination of durability and design is what makes bakery labels unique. It must be both practical and visually appealing. A great bakery label doesn’t just identify what’s inside the package; it reflects the care, quality, and creativity behind every item you bake.

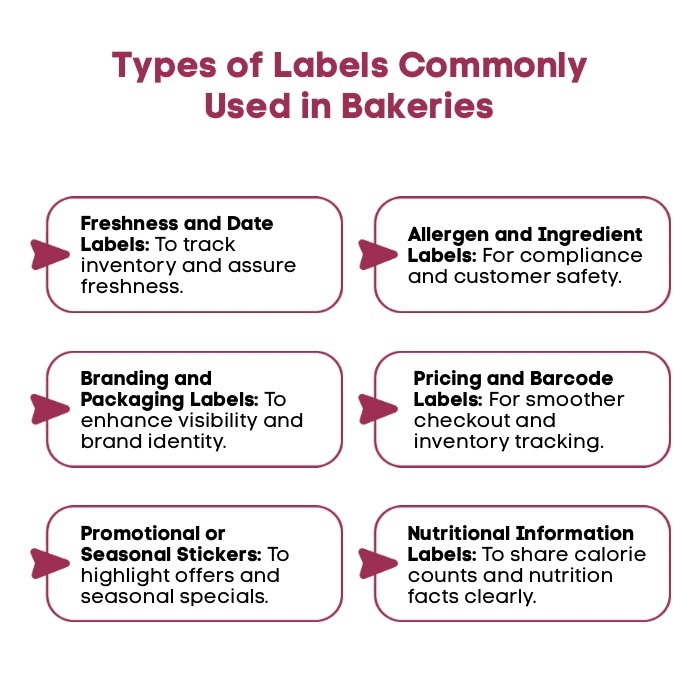

What Types of Labels Do Bakeries Commonly Need?

Not all bakery labels serve the same purpose. Some help customers make quick, informed choices, while others keep your products compliant, organized, and on-brand. Understanding the main label types makes it easier to choose the right materials, designs, and printer setup.

Here are the most common label types bakeries use:

-

Freshness and Date Labels: These show “baked on,” “best before,” or “sell by” dates. They help track inventory and reassure customers about product freshness.

-

Allergen and Ingredient Labels: Essential for compliance and customer safety. They list allergens like nuts, dairy, or gluten, along with full ingredient details in clear, legible print.

-

Branding and Packaging Labels: These carry your bakery’s personality like logo, tagline, and design. They make your packaging instantly recognizable and help boost brand recall.

-

Pricing and Barcode Labels: Printing barcode and pricing labels are useful for POS systems and inventory management. They help staff process transactions quickly and reduce pricing errors.

-

Promotional or Seasonal Stickers: Perfect for limited-time offers, holiday specials, or new launches. They add visual appeal and encourage impulse purchases.

-

Nutritional Information Labels: Increasingly important for pre-packaged bakery goods. They provide calorie counts, serving sizes, and nutritional facts in a clear, compliant format.

When chosen thoughtfully, each label adds a layer of trust, clarity, and charm. Together, they turn simple packaging into a professional, polished experience that customers remember.

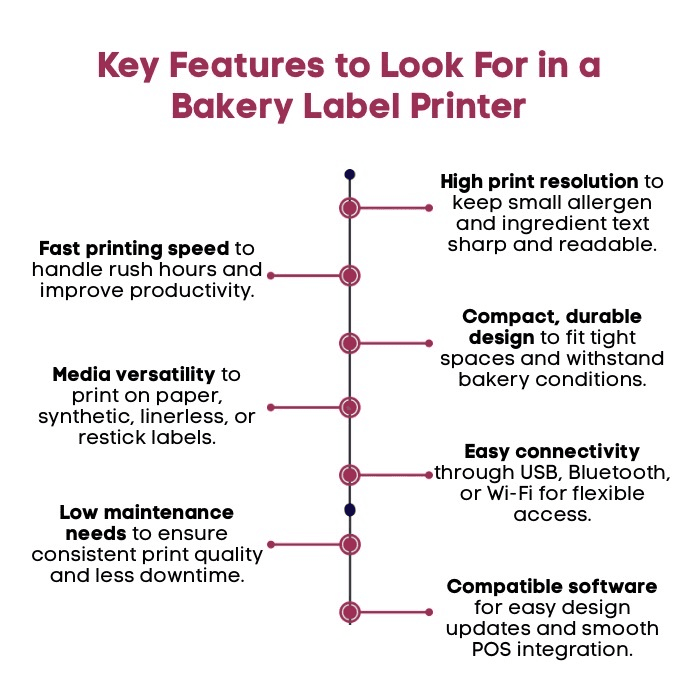

What Key Features Should You Look for in a Bakery Label Printer?

Choosing the right bakery label printer can make the difference between smooth, consistent labeling and constant frustration. Bakeries face unique challenges, from hot ovens and crowded counters to time-sensitive labeling, so it’s not just about print speed or size; it’s about reliability, clarity, and ease of use.

Here’s what to look for when picking your bakery label printer:

-

High Print Resolution: Small allergen text and ingredient lists must stay sharp and easy to read. A printer with at least 203 DPI ensures crisp details so labels look professional and meet food safety standards.

-

Fast Printing Speed: During the morning rush, every second counts. A fast printer helps you label products quickly and keep display shelves stocked without delays.

-

Compact, Durable Design: Space is limited, and bakeries get messy. Choose a compact printer that fits on a crowded counter and resists heat, humidity, and flour dust.

-

Media Versatility: From glossy branding labels on pastry boxes to linerless freshness tags on bread trays, flexibility matters. The right printer can handle multiple label types without switching equipment.

-

Easy Connectivity: Staff should be able to print from wherever they are, whether it’s the prep area or the front counter. Bluetooth, USB, or Wi-Fi options keep labeling fast and flexible.

-

Low Maintenance Needs: With ovens running and orders stacking up, downtime isn’t an option. Look for an easy-to-clean, drop-in-loading printer to keep things running smoothly.

-

Compatible Software: The ability to sync with your POS or recipe management system means label updates, such as new ingredients or seasonal designs, happen in seconds.

A great bakery label printer doesn’t just print labels; it keeps your workflow organized, your products compliant, and your branding consistent from the first batch to the last.

Want to boost speed and cut labeling costs? Find out why more businesses are switching to 4x6 thermal label printers and how it can streamline your bakery’s workflow.

Why Does the SLP-721 Excel for Bakery Labeling Tasks?

The Seiko SLP-721 is designed for precision and reliability, which is exactly what bakeries need to keep up with fast-moving production and display demands. Compact, efficient, and built for daily use, it delivers clean, durable labels that stay sharp and legible from the oven to the counter.

Key Specifications

-

Print Method: Direct thermal

-

Print Speed: Up to 200 mm/sec (7.87 ips)

-

Print Resolution: 203 dpi for clear, detailed text

-

Print Width: 2 inches (supports 40 mm or 58 mm media)

-

Media Type: Linerless labels, standard labels, and receipt paper

-

Connectivity: Bluetooth and USB

-

Size: Compact design ideal for limited counter space

Why It Stands Out for Bakeries

-

Linerless Label Capability: Prints on liner-free labels, perfect for quick peel-and-stick use in busy bakery environments.

-

Fast and Consistent Output: High print speeds keep production flowing, even during rush hours.

-

Compact and Durable: Takes minimal space on crowded counters and withstands daily heat, humidity, and flour dust.

-

Sharp Print Clarity: Maintains clean, legible allergen text, freshness dates, and fine branding details.

-

Flexible Media Support: Works with both linerless and traditional labels, ideal for freshness, allergen, or pricing needs.

-

Easy Connectivity: Bluetooth and USB options make it simple to integrate with existing bakery systems.

The SLP-721 combines speed, precision, and versatility: everything a bakery needs to label products efficiently while keeping packaging neat, compliant, and professional.

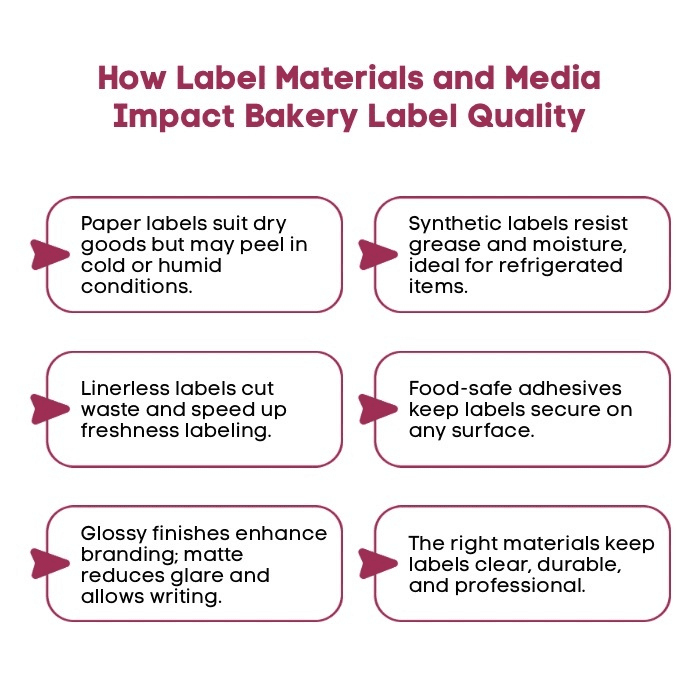

How Do Label Materials and Media Affect Bakery Label Quality?

The right label material can make or break how your bakery products look, and how long that look lasts. Between heat, moisture, and handling, bakery labels face more challenges than most. Choosing the right media ensures your labels stay readable, stick well, and look great all day.

Here’s what to consider when selecting label materials:

-

Paper Labels: Ideal for short-term use on dry packaging like cookie bags or pastry boxes. They’re affordable and deliver excellent print quality, but if your cookies sit in a refrigerated display, paper labels may curl or peel by lunchtime.

-

Synthetic Labels: Made from materials like polypropylene, these resist grease, moisture, and temperature changes. Perfect for refrigerated cakes, deli sandwiches, or any product exposed to condensation.

-

Linerless Labels: Great for high-speed environments, these reduce waste and speed up labeling for “baked today” or “fresh batch” stickers during morning prep.

-

Adhesive Quality: Opt for food-safe adhesives that can hold on both paper boxes and plastic containers — even when exposed to steam or chilled cases.

-

Finish and Coating: Glossy finishes make logos and colors pop on display shelves, while matte finishes are ideal for writable date or allergen fields.

In bakery settings, the right label isn’t just about looks; it’s about performance. Whether it’s a croissant label that stays crisp next to a warm tray or an allergen tag that won’t smear in the fridge, your media choice directly impacts how your brand and freshness are perceived.

Looking for the best waterproof label printer? Check out our latest reviews and comparison of the best waterproof label printers.

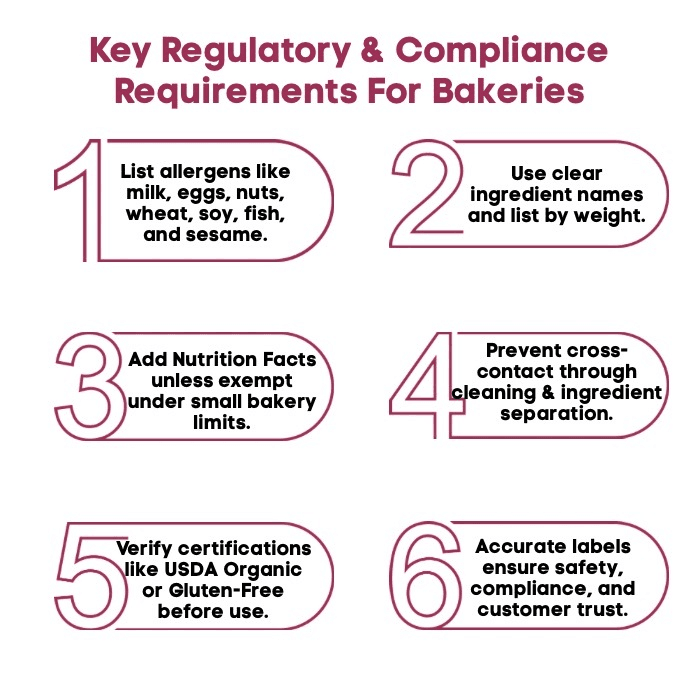

What Regulatory and Compliance Requirements Should Bakeries Consider?

Bakery labels do more than display ingredients; they communicate trust and safety. In the U.S., every label must meet clear legal standards to protect consumers and ensure product transparency. Getting compliance right isn’t optional; it’s part of running a professional bakery.

Here’s what every bakery should keep in check:

-

Allergen Disclosure: Labels should include a clear product warning for major allergens such as milk, eggs, nuts, wheat, soy, fish, shellfish, and sesame, with a “Contains” statement placed immediately after the ingredient list.

-

Accurate Ingredient Lists: List ingredients by weight using common names. Avoid vague terms and ensure all claims, such as “gluten-free,” are honest and verifiable.

-

Nutrition Labeling: Most packaged goods need a Nutrition Facts panel. Small bakeries may qualify for exemptions if they meet specific sales limits, but should still maintain accurate records.

-

Cross-Contact Prevention: Clean equipment, separate ingredients, and follow Good Manufacturing Practices to prevent undeclared allergens.

-

Certifications and Claims: If your labels include certifications like USDA Organic, Non-GMO Project Verified, Kosher, or Certified Gluten-Free, they must meet the certifying body’s standards. Unverified or outdated claims can lead to compliance issues or penalties.

Accurate and compliant labeling protects your customers and your brand. It turns legal responsibility into a clear sign of professionalism and trust.

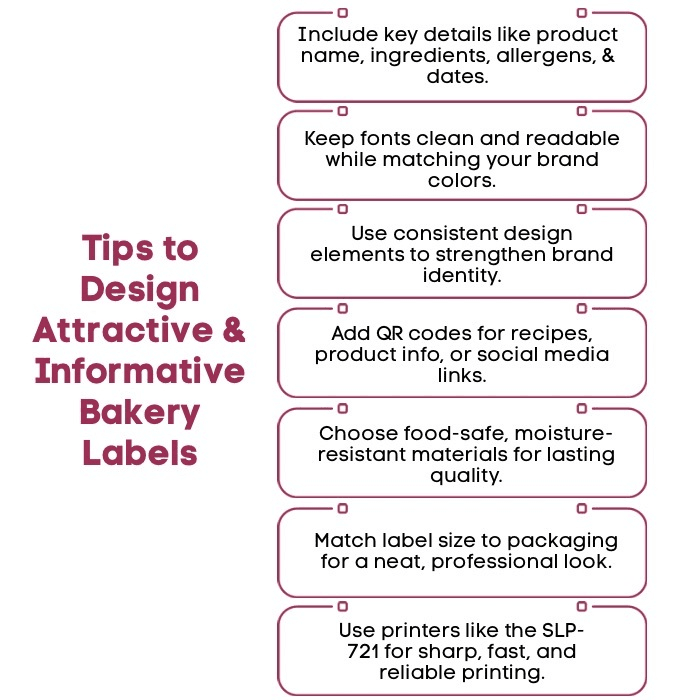

How Can You Design Bakery Labels That Are Both Attractive and Informative?

A great bakery label doesn’t just tell customers what they’re buying; it makes them want to pick it up. The right design blends creativity, clarity, and compliance to create labels that look beautiful and communicate all the vital information at a glance.

Keep these key points in mind while designing your bakery labels:

1. Start With the Essentials

Every bakery label should include the product name, ingredient list, allergens, production dates, and expiration dates. These details aren’t just about regulations; they also build trust and transparency with your customers.

2. Balance Style With Readability

Choose fonts and colors that reflect your brand image but remain easy to read. Keep text crisp and legible, especially for small label sizes. Use clear headers for key details like allergens or “freshly baked” to draw quick attention.

3. Use Design to Tell Your Brand Story

Your bakery’s logo, color palette, and tone all shape how customers perceive your brand. Consistent, clean product labels help even small businesses look polished and professional. If you’re a home baker or cottage food producer, custom labels can make your goods look store-ready.

4. Include Useful Elements

Add QR codes for recipes, nutritional info, or social media links. This helps connect your in-store packaging to your online presence and keeps customers engaged beyond the purchase.

5. Match Materials to Your Needs

Use food-safe materials that suit your packaging. For example, fresh food labels or deli food labels need strong adhesion and moisture resistance. The right material keeps your design intact from the kitchen to the display.

6. Choose Print Technology That Supports Quality

Modern printers like SLP-721 offer rapid printing speed and clear text, making it ideal for bakeries that print often. With advanced features like compatibility, you can easily update designs or print new batches on demand.

Quick Tip: Store label rolls in a label holder to prevent smudging and ensure smooth printing. Whether you use direct thermal labels, thermal transfer printing, or inkjet printers, always test your design for clarity and durability before full production.

Ready to take your bakery branding up a notch? Explore the latest color label printing trends small businesses should know to stay ahead of the curve.

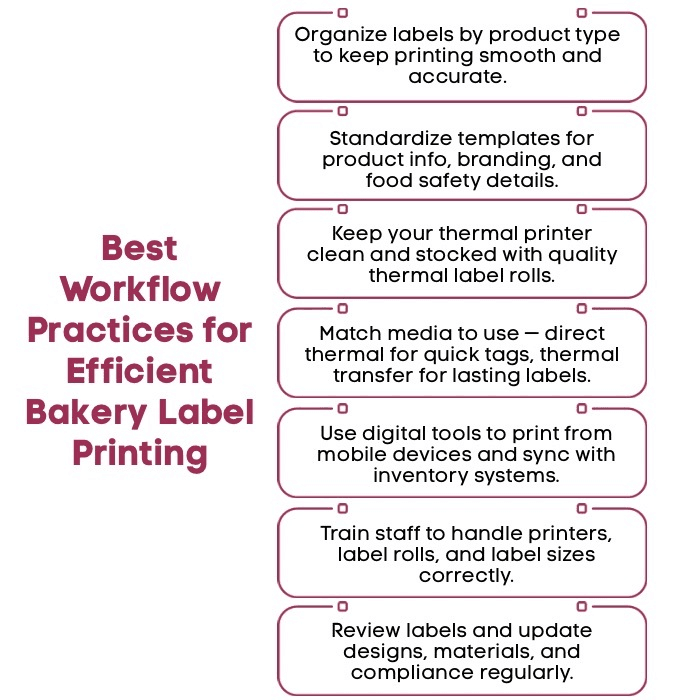

What Are the Best Workflow Practices for Efficient Bakery Label Printing?

Running a bakery means every second counts, and your label printing process should keep up with that pace. Efficient labeling isn’t just about speed; it’s about consistency, accuracy, and minimizing waste while maintaining professional quality.

1. Organize Labels by Product Categories

Group your product labels by type, like daily bakes, seasonal items, or special orders. This helps streamline printing sessions and ensures the right label goes on the right packaging every time.

2. Standardize Label Templates

Create consistent templates for your product info, brand layout, and food safety details. Whether printing for fresh pastries or prepackaged items, standardized designs reduce errors and make updates quick and simple.

3. Maintain Your Printer and Supplies

Keep your thermal printer clean and stocked with the right thermal label rolls. Replace worn parts regularly and store supplies properly to prevent misalignment or smudging. A well-maintained printer ensures sharp text, accurate barcodes, and reliable results shift after shift.

4. Choose the Right Label Media

Match your labels to the job. Use direct thermal printing for quick, disposable labels like freshness tags, and thermal transfer for long-lasting ones like shipping labels or product branding. The right media prevents fading and helps maintain a polished look.

5. Use Digital Tools for Flexibility

Apps allow you to manage label printing directly from mobile devices, ideal for bakery owners who juggle multiple tasks. Integrating your label printing with inventory systems also keeps production smooth and prevents labeling mix-ups.

6. Train Staff for Consistency

Even with advanced technology, proper training for staff matters. Train your team on how to use your printer efficiently, load label rolls correctly, and verify label size and layout before printing. A little training goes a long way in avoiding costly reprints.

7. Review and Update Regularly

As your menu or packaging evolves, so should your labels. Periodically review your label printing process, materials, and compliance details like cottage foods label requirements. This keeps your workflow efficient and your bakery fully up to date.

OmegaBrand: Your Trusted Partner for the Seiko SLP-721 Bakery Label Printer

Great bakeries know that presentation matters as much as flavor. That is why professionals choose OmegaBrand, the trusted source for the Seiko SLP-721 Bakery Label Printer, designed to deliver speed, precision, and lasting clarity in every print.

OmegaBrand combines proven expertise with advanced labeling technology to help bakeries create labels that remain sharp, legible, and compliant, even in warm or refrigerated environments. The Seiko SLP-721 stands out for its fast printing speed, compact design, and 203 dpi resolution, making it ideal for freshness tags, allergen labels, and custom branding.

When you choose OmegaBrand, you gain more than a printer. You gain access to genuine Seiko supplies, high-quality label rolls, and dedicated support that keep your labeling workflow efficient from kitchen to counter. Every label you print reflects your craftsmanship, and at OmegaBrand we ensure that it meets the highest standards of quality and consistency.

Ready to upgrade your bakery labeling setup? Book a free call with us today to get expert guidance and personalized support.

What’s the Takeaway for Smooth, Reliable Bakery Label Printing?

Smooth bakery label printing is about precision, consistency, and presentation. It ensures every loaf, pastry, or cookie leaves your counter looking professional and compliant with all labeling standards.

For both bakery owners and home bakers, the key lies in combining the right tools with the right process. A dependable thermal printer, proper label rolls, and clear label templates help maintain accuracy and save time.

Consistent use of quality materials ensures food labels stay legible and durable, whether displaying product ingredients, production dates, or expiration dates. Choosing the right label size and print method, such as thermal transfer or direct thermal printing, guarantees clarity and reliability.

At the end of the day, bakery label printing is not just about function. It’s about reinforcing food safety, brand image, and customer trust with every label you print.

Frequently Asked Questions

What makes a label truly “food-safe”?

A food-safe label uses approved materials and adhesives that won’t contaminate food. These labels resist grease, moisture, and temperature changes while staying legible and securely attached.

Can the SLP-721 print very small allergen text clearly?

Yes. With its 203 dpi resolution and precise direct thermal printing, the SLP-721 produces crisp, readable text, making even small allergen or ingredient details easy to see.

How long will freshness or bake date labels stay legible in refrigeration or display?

High-quality direct thermal or thermal transfer labels remain clear for days or weeks, depending on exposure to light, moisture, and temperature. Using durable label materials helps preserve print quality.

Which label adhesives work best for greasy or moist packaging?

Permanent food-safe or freezer-grade adhesives perform best on oily, chilled, or damp surfaces. They stick firmly to paper boxes, plastic containers, and deli food labels without peeling.

Is linerless or restick labeling better for bakery settings?

Linerless labels minimize waste and are great for quick freshness or expiration labeling. Restick labels are ideal for reusable containers or temporary tags. Choose based on your packaging and workflow needs.

How often should the printer be cleaned or maintained to prevent smudging or misalignments?

Clean your thermal printer weekly if used frequently or after every few label rolls. Regular cleaning prevents buildup from flour, grease, and adhesive, ensuring smooth feeding and consistent print quality.

Where can I buy bakery label printers for small businesses?

You can buy bakery label printers from OmegaBrand, which offers a wide range of reliable, affordable options for small businesses. They also provide label rolls, holders, and accessories, making it easy to set up a complete label printing system tailored to bakery operations.

What is the best printer for making bakery product labels on a budget?

The Seiko SLP-721 is an excellent budget-friendly choice for bakery label printing. It delivers crisp 203 dpi resolution, rapid printing speed, and reliable performance using direct thermal printing technology, making it perfect for producing ingredient, allergen, and freshness labels efficiently without high ongoing costs.