How to Choose the Right Product Identification Labels?

11th Jul 2025

Have you ever had your labels fade, peel off, or just not stick where they should? It's frustrating, especially when clear identification is critical for safety, compliance, or tracking. Choosing the wrong product labels can cost you time, money, and trust. Your labels must withstand extreme temperatures, rough handling, or chemical exposure. So, how do you pick the right ones that actually last? Let's break it down.

Introduction to Product Identification Labels

Every organization values product identification labels for branding consistency. They differentiate goods, ensure traceability, protect against counterfeits, prevent theft, and enhance brand reputation. With various materials like vinyl, PVC, polyester, and thermal options available, these labels offer flexible application.

Utilizing advanced printing techniques, including die-cut and in-mold options, they capture essential data and withstand harsh conditions, key business traits. Think of these labels as communication tools that help customers understand your product while effectively positioning your brand in a competitive market. Let's explore the world of product identification labels further.

Ready to Upgrade Your Product Labeling with Durable, High-Performance Solutions? Contact OmegaBrand Today!

What Are Product Identification Labels?

Product identification labels are crucial for distinguishing products in retail and logistics. They typically display essential information, such as barcodes, product names, and usage instructions, ensuring efficient inventory management and aiding consumers in making informed choices during their shopping experience.

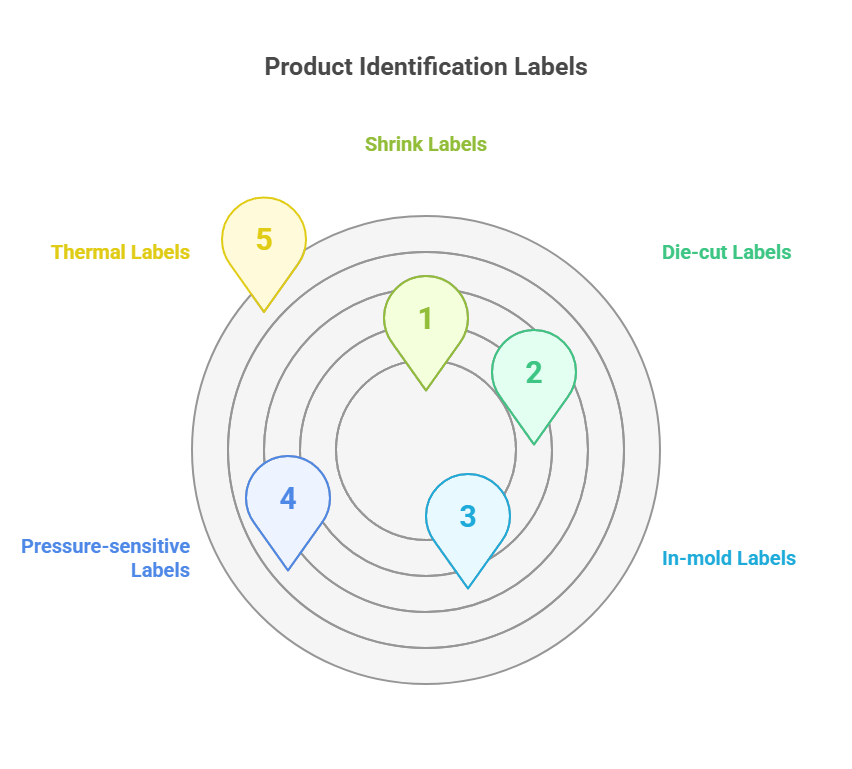

What Are the Types of Product Identification Labels?

Product identification labels come in various types, each serving specific purposes. Common types include shrink, die-cut, in-mold, and pressure-sensitive labels. Understanding these options allows businesses to select the most suitable product label based on application and design needs.

1. Shrink Labels

Shrink labels are versatile packaging solutions that tightly conform to heated product contours. This process enhances visual appeal by creating a seamless label design. Their durability and moisture resistance make them ideal for regulatory environments like the food and beverage industries. Additionally, shrink labels aid in traceability and combat counterfeiting, making them suitable for various sectors.

2. Die-cut Labels

Die-cut labels offer a sleek, professional look tailored to specific needs. They enhance brand recognition with compelling designs and come in durable materials like vinyl and BOPP. These labels adhere well to different surfaces, ideal for packaging and ensuring regulatory compliance and traceability. The precision of die-cutting enables intricate designs that transition smoothly from printing to application, optimizing performance in commercial and industrial settings.

3. In-mold Labels

In-mold labels provide an innovative solution for product identification by integrating with packaging during the molding process. This technique enhances durability and adheres exceptionally well to surfaces like PVC and BOPP, making it suitable for aerospace and consumer goods industries. With high design flexibility, these labels can feature intricate graphics and barcodes, ensuring regulatory compliance and preventing counterfeiting. They guarantee traceability while maintaining a consistent aesthetic across products.

4. Pressure-sensitive Labels

Pressure-sensitive labels provide a versatile and convenient labeling solution. These adhesive labels firmly stick to various surfaces, ensuring durability without extra machinery. Perfect for packaging, shipping, and product identification, they maintain regulatory compliance and enhance traceability. Available in materials like vinyl and BOPP, they can be customized through techniques such as screen printing. Their self-adhesive feature simplifies application, making them a favored choice for manufacturers across industries.

5. Thermal Labels

Thermal labels are printed using focused heat to generate an image on the label material. They are widely used for barcoding due to their printing speed, precision of barcode lines (also known as "white lines"), and low maintenance requirements. Available in direct thermal labels that use heat for color change and thermal transfer labels that use heat to melt onto the substrate, these offer durability under adverse conditions.

Printers to Look Out For

Brother TD-4750TNWBCS Industrial Label Printer

The Brother TD-4750TNWBCS is a powerful industrial thermal transfer printer ideal for printing durable, high-resolution compliance labels, barcodes, and product identifiers. Built with enterprise-grade performance in mind, it's suited for manufacturing, warehousing, and retail backroom environments.

Key Features:

-

Thermal transfer and direct thermal printing

-

300 dpi print resolution for crisp, scannable barcodes

-

Built-in Wi-Fi, Ethernet, and USB connectivity

-

Supports a variety of media, including pre-printed labels

-

Advanced security protocols for enterprise environments

-

Includes cutter

Pros:

-

Excellent print quality, especially for barcodes

-

Multiple connectivity options for flexible integration

-

Rugged design suitable for industrial use

-

Compatible with Brother's P-touch Editor for easy label design

Cons:

-

May require some setup for full feature access

-

Slightly highe

Godex G530 Desktop Barcode Printer

The Godex G530 is a desktop barcode printer built for small—to medium-sized industrial labeling tasks. It features 300 dpi resolution and supports a range of label materials, offering reliable, high-quality performance in compact form.

Key Features:

-

300 dpi resolution for detailed text and barcodes

-

Dual sensor system for precise label detection

-

Supports both direct thermal and thermal transfer printing

-

USB, serial, and Ethernet connectivity

-

Easy media loading and calibration

Pros:

-

Sharp output, even for small fonts and complex barcodes

-

Compact footprint for limited workspace

-

Affordable yet feature-rich

-

Compatible with various label sizes and materials

Cons:

-

Not ideal for highly high-volume environments

-

Lacks built-in Wi-Fi (requires external adapter)

-

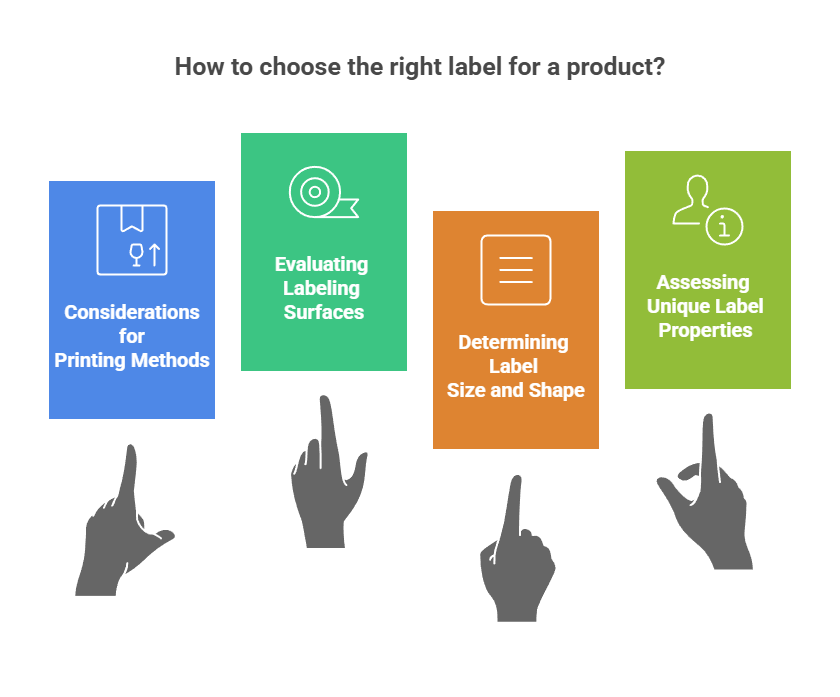

How to Choose the Right Label for Your Product?

When picking the perfect label, don't just grab the first one that sticks—literally! Think about your product's size, shape, and surface. Is it smooth, curved, or textured? Then factor in durability, adhesion, and how it'll be printed. Will it face heat, moisture, or chemicals? And let's not forget your branding—your label should look sharp and meet all compliance standards. It's not just a label; it's your product's voice.

1. Considerations for Printing Methods

The printing method depends on your label's material, design, and intended use. Flexographic Printing is ideal for custom roll labels and packaging, providing precision and durability. Digital Printing suits high-quality products like graphic overlays, banners, and vehicle wraps, delivering vibrant colors and clear details. For precise shapes or prototypes, Laser Cutting may be necessary. Silk Screen Printing or UV inks are effective options if your labels require fine details and bright colors.

2. Evaluating Labeling Surfaces

Labeling surfaces is crucial for effective product identification. Materials like PVC and vinyl affect adhesion and durability, ensuring labels stick under various conditions. Evaluating surface texture and cleanliness is essential to maintain consistency and performance. Compliance with regulatory and military standards is vital in industrial settings, such as aerospace or circuit boards. Assessing these factors enhances the reliability and traceability of your labels.

3. Determining Label Size and Shape

Label size and shape should match your product's attributes and the information you want to convey. Smaller products need concise labels, while larger items can accommodate more detailed ones. The product's shape also influences label design; flat surfaces allow for more flexibility, while curved or irregular shapes may require custom die-cut labels. Wraparound labels are ideal for cylindrical or round products.

4. Assessing Unique Label Properties

Labels may need specific properties based on your product and application. Labels resistant to electrical charges or high temperatures are crucial for electronic components. Food and pharmaceutical products may require water-resistant labels that can withstand freezing or refrigeration. Features like tamper-evident or safety seals enhance security by deterring unauthorized access. In some cases, labels that reveal a visible void pattern upon removal can prevent unauthorized transfer.

Tired of Labels That Don’t Last? Discover OmegaBrand’s Durable Labeling Solutions That Stick, Stay, and Stand Out!

Are you struggling with items that fade, peel, or don't hold up? OmegaBrand's product identification labels are built for durability, clarity, and compliance, regardless of shape, surface, or environment. From harsh industrial conditions to sleek retail packaging, our labels stay put and showcase your brand beautifully. Ready for labeling that performs as well as your product? Let's talk! Contact OmegaBrand today and discover your perfect label solution.

Conclusion

Product identification labels serve multiple purposes, providing essential information and enhancing brand image. They are crucial for quality control, inventory management, authenticity verification, and marketing throughout a product's lifecycle. Selecting the proper labels requires understanding your product's environment, intended use, labeling surface, and specific requirements. Regardless of sector differences, labels are essential in today's marketplace. With advancements in label technology, businesses can easily find suitable options. Choosing the correct label is vital for product success and brand promotion in a competitive landscape.

Frequently Asked Questions

What factors should I consider when selecting a product identification label?

When selecting product identification labels, consider durability, print quality, adhesive type, and label size. Additionally, evaluate compatibility with your packaging materials and printing methods to ensure the labels adhere properly and withstand environmental factors. These considerations will help optimize your labeling strategy.

How do different label types impact the identification process?

Different label types affect visibility, durability, and application ease, directly influencing product identification. For example, pressure-sensitive labels offer quick application and repositioning, while in-mold labels provide a seamless look. Choosing the right type enhances brand recognition and ensures compliance in various industries.

What are the best practices for implementing product identification labels in my business?

To effectively implement product identification labels, ensure clarity and consistency in design, choose durable materials, and comply with regulatory requirements. Additionally, regularly review labeling processes for efficiency and train staff on proper labeling techniques to enhance accuracy and compliance.

How do product identifiers prevent counterfeits?

Product identifiers, like unique barcodes or holograms, are crucial in preventing counterfeits by providing verifiable information about the product's origin and authenticity. This enables consumers to distinguish genuine items from fakes, enhancing trust and reducing the risk of fraud.