Which Label Printing Trends Should You Watch in 2025?

23rd Oct 2025

Key Highlights

-

Linerless labels are seeing strong global growth as brands cut material waste and improve sustainability.

-

Eco-friendly label materials are expected to reach USD 2,374 million in sales by 2034, growing at a 4.3 percent CAGR.

-

Hybrid printers like the SLP-700 Series offer flexible media handling for labels, receipts, and linerless formats.

-

Faster print speeds and automation are helping businesses handle higher volumes under tighter deadlines.

-

Connectivity and API integration enable real-time printing, better data accuracy, and fewer manual errors.

-

Durable printers with long cutter life reduce downtime and deliver greater long-term value.

-

Smart labels, QR codes, and RFID technology are driving traceability and regulatory compliance across industries.

-

Adopting these label printing trends now helps future-proof your business and strengthen brand credibility.

Last year, thermal printers dominated every packaging line. This year, it’s all about linerless labels, recyclable films, and smart tags that track every product from factory to shelf. The pace of change in label printing isn’t slowing down, but accelerating. For businesses juggling tight production schedules and sustainability goals, keeping up with these shifts isn’t just challenging; it’s mission critical.

The real challenge is knowing which label printing trends actually matter. With new materials, stricter labeling laws, and automation creeping into every corner of the supply chain, it’s easy to get overwhelmed by options. Many businesses end up stuck with outdated equipment or processes that can’t deliver the flexibility or compliance today’s market demands.

That’s exactly why we put this guide together. In this blog, we’ll walk you through the biggest label printing trends shaping 2025, explain why they matter for your business, and show how the right technology can help you stay ahead instead of just keeping up.

Why Label Printing Trends Matter for Businesses?

If you’re running a business in 2025, keeping up with label printing trends is no longer optional. The way labels are designed, printed, and delivered is changing fast, and those shifts directly affect how your products are seen, sold, and trusted.

New expectations from customers and tighter regulatory compliance mean your product label has to work harder than ever. It needs to share detailed product information, support QR codes or smart labels for instant engagement, and align with recyclable materials or compostable labels to meet sustainability goals. Ignoring these shifts could leave your brand looking outdated or out of touch.

The packaging industry is also under pressure from shorter print runs, faster turnaround times, and real time data demands. Staying on top of these key trends helps you manage supply chain efficiency, maintain consistency across product lines, and keep your brand image strong even under tight deadlines.

Now is the time for small business owners and brand owners alike to pay attention. Those who adapt quickly to the latest label printing innovations will gain a clear competitive edge in today’s business climate.

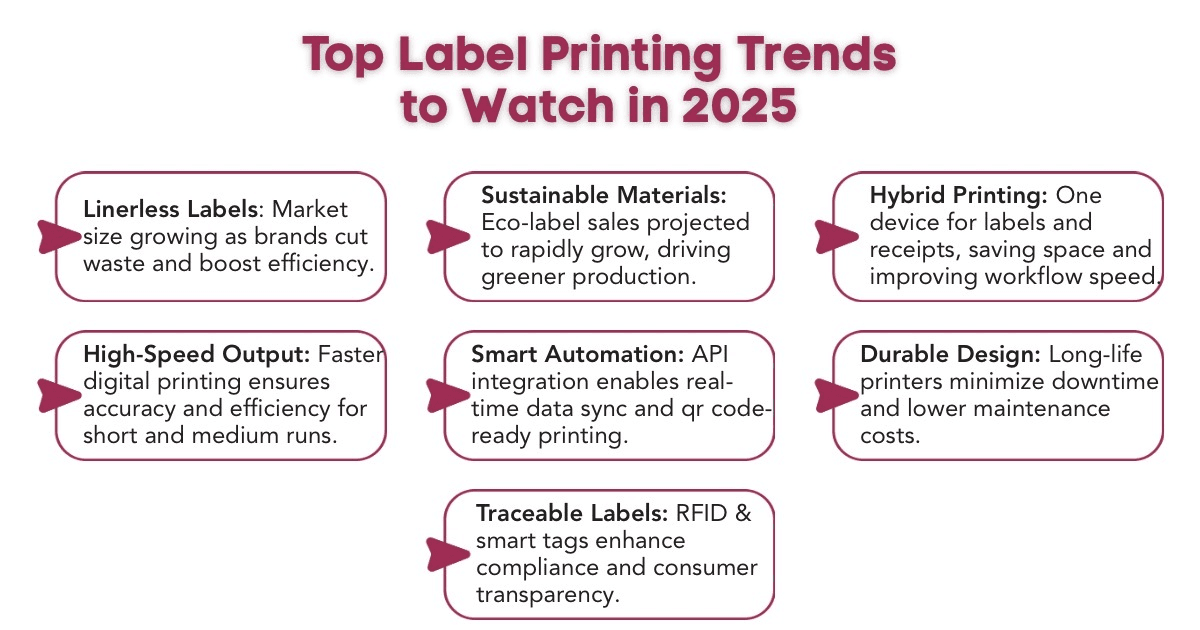

What Are the Top 7 Label Printing Trends Shaping 2025?

The label printing landscape is changing fast as new technologies, consumer expectations, and sustainability goals push businesses to rethink how they design and produce their labels. Staying ahead of these changes can help companies streamline workflows, cut costs, and strengthen brand trust. Here’s a look at the key label printing trends shaping 2025 and why businesses should pay attention right now.

Trend 1: Growth in Linerless Label Adoption

Linerless labels are becoming a favorite for businesses that want efficiency and less waste. Unlike traditional labels, they eliminate the need for a backing liner, saving on materials and storage space. The global linerless labels market is projected to grow from about USD 2.1 billion in 2025 to USD 3.2 billion by 2035, reflecting a steady CAGR of around 4.2%.

For companies managing high print volumes, linerless technology improves throughput, reduces downtime, and supports sustainability goals without compromising quality.

Trend 2: Sustainability and Eco-Materials in Label Printing

Sustainability has shifted from a trend to a must-have. The global sales of sustainable labels are estimated to be worth USD 1,558.3 million in 2024 and are projected to reach USD 2,374 million by 2034, growing at a CAGR of 4.3%.

More companies are using recyclable materials, compostable labels, and lower-impact inks to reduce their environmental footprint. This approach not only meets regulatory requirements but also appeals to eco-conscious customers who value transparency and responsibility.

Trend 3: Hybrid Label and Receipt Printers with Media Flexibility

Businesses are embracing hybrid printers that handle both labels and receipts in one device. This flexibility reduces the need for multiple machines, saving money and workspace. For small business owners and retail operators, this setup simplifies workflows, improves speed, and helps maintain consistent label quality across different print types.

Trend 4: Faster Print Speeds and Throughput Gains

Speed now defines efficiency in label printing. New digital printing technology allows companies to manage short and medium runs faster while maintaining accuracy. Higher print speeds minimize downtime, improve productivity, and help businesses meet customer demand for quick turnaround. This capability gives brand owners more control over their production timelines and overall output.

Trend 5: Connectivity, API Integration, and Automation

Automation and connectivity are transforming how label printing works. Modern label printers connect through APIs, syncing data in real time with design platforms, inventory systems, and logistics tools.

This integration supports variable data printing for batch tracking or QR codes, improving consistency and accuracy across all print jobs. Businesses that automate labeling can adapt faster to demand changes and reduce manual errors.

Trend 6: Durability, Reliability, and Long Printer Life

With continuous operations becoming the norm, reliability is more important than ever. Manufacturers are designing label printers with stronger components and longer lifespans to meet round-the-clock production needs.

Durable machines reduce maintenance costs, limit downtime, and deliver consistent performance over time, making them a solid long-term investment for both small and large-scale businesses.

Trend 7: Regulatory and Traceability Demands

Regulatory standards across industries are becoming stricter, and traceability has become essential. Businesses are turning to smart labels and RFID tags to ensure every product is traceable throughout the supply chain.

These solutions help maintain compliance, improve product transparency, and build customer trust. Labels now carry more than brand identity; they communicate safety, authenticity, and accountability.

How the SLP-700 Series Aligns with These Trends?

The SLP-700 Series, which includes Seiko’s SLP720RT and SLP721RT models, represents a new generation of smart, compact label printers built for flexibility, sustainability, and speed. Designed to handle linerless, standard, and receipt media, these printers deliver the reliability and innovation that modern businesses need.

Here’s how the SLP-700 Series aligns with the biggest label printing trends shaping 2025.

1. Supporting the Shift Toward Linerless Label Adoption

The SLP-700 Series fully supports linerless label printing, making it a perfect fit for companies aiming to reduce waste and optimize space. By removing the need for liners, these printers help lower material costs and simplify storage.

Their direct thermal print method offers fast, efficient output without the extra waste, aligning directly with the industry’s growing commitment to sustainable and lean operations.

2. Driving Sustainable Labeling Practices

Sustainability is central to the SLP-700 lineup. With global sustainable label sales expected to reach USD 2,374 million by 2034, businesses are under pressure to choose equipment that minimizes environmental impact.

The SLP-700 Series is engineered for that goal, its linerless compatibility and energy-efficient design reduce waste and carbon footprint. For brands focusing on eco-conscious production, this series provides a reliable, ready-to-implement solution.

3. Built for Hybrid Flexibility

The SLP-700 Series can handle multiple media types, including linerless labels, receipt paper, and standard labels with liners. This hybrid versatility is ideal for small business owners and retail environments where every inch of workspace matters.

Whether printing product labels, receipts, or barcodes, users can count on consistent quality and smooth operation from one compact device.

4. Optimized for Speed and Throughput

Speed is one of the SLP-700 Series’ strongest features. With print speeds up to 7.87 inches per second and a resolution of 203 dpi, it balances precision with performance.

This makes it perfect for handling short runs, continuous printing, or high-volume workflows under tight deadlines. Faster throughput helps businesses boost productivity and maintain consistent labeling even during peak demand.

5. Seamless Connectivity and Automation

The SLP-700 Series comes with multiple connectivity options, including USB, Ethernet, Bluetooth, and WiFi. These interfaces make it easy to integrate with POS systems, mobile devices, and labeling software for real-time printing and data management.

This connectivity supports automation and variable data printing, giving businesses the flexibility to include QR codes, batch numbers, or expiry details with minimal manual effort.

6. Long-Term Durability and Reliability

Reliability defines the SLP-700 Series. With a cutter life of up to one million cuts for linerless labels, these printers are built to perform in high-demand environments.

The strong internal components and durable exterior ensure steady operation with minimal maintenance, which is essential for businesses that rely on consistent uptime and long-term value.

7. Meeting Regulatory and Traceability Needs

The SLP-700 Series supports printing barcodes, QR codes, and GS1-compliant data formats, which are critical for traceability and regulatory compliance. From food labeling to healthcare and logistics, these features make it easier for businesses to stay compliant while providing clear and accurate product tracking. The result is improved consumer trust and better control across the supply chain.

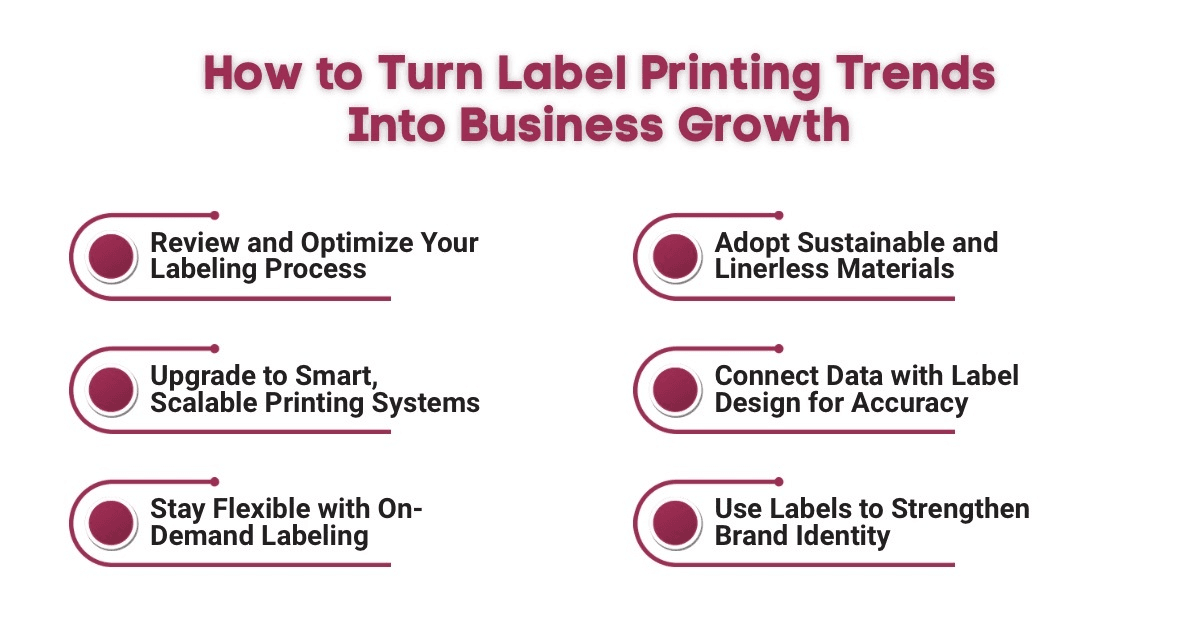

What These Trends Mean for Your Business: Actionable Advice

These label printing trends are not just shaping the industry; they are transforming how modern businesses operate. Adapting now means smoother workflows, stronger compliance, and better customer connections. Here’s how to act on them effectively.

1. Audit Your Current Labeling Workflow

Start by reviewing how your labels are created, printed, and managed. Look for inefficiencies such as wasted material, frequent reprints, or manual data entry. Even small upgrades, such as switching to digital printing or automating approvals, can save time and reduce costs in the long run.

2. Set Clear Sustainability Goals

Eco-friendly labeling is becoming a compliance requirement. Identify where you can adopt recyclable or linerless materials and work with suppliers who align with your sustainability targets. Track your progress so you can showcase measurable impact to customers and partners.

3. Future-Proof Through Technology

Invest in systems that can evolve with your business. Choose label printers and software that allow cloud connectivity, real-time updates, and flexible media use. A scalable setup ensures you will not need to overhaul your printing process every time your product line or regulatory needs change.

4. Integrate Data and Design

Data-driven labeling is becoming the norm. Use your internal systems to feed product details, batch numbers, and QR codes directly into your label templates. This creates consistency and accuracy across all channels, which is critical for brand integrity and traceability.

5. Build for Agility

Markets shift fast, and your labeling setup should too. Opt for equipment and processes that can handle short runs, on-demand edits, and rapid design changes. This agility keeps you responsive to consumer demand, seasonal promotions, or new product launches.

6. Treat Labeling as Brand Communication

Your label is not just packaging; it is your brand’s first impression. Focus on clarity, durability, and visual appeal. A well-designed label builds instant trust, helps customers find vital information easily, and reinforces your identity every time they interact with your product.

Why Choose OmegaBrand for Your Label Printing Solutions

At OmegaBrand, we understand that your labeling process is more than just printing; it’s how your business communicates, complies, and connects. That’s why we go beyond selling products to deliver complete labeling solutions tailored to your needs.

Whether you’re a small business owner upgrading to smarter printing systems or part of a large operation optimizing speed and traceability, we’ve got you covered. We carry top brands like Seiko, Zebra, and Epson, including the advanced SLP-700 Series, known for its linerless flexibility, high-speed performance, and long-term reliability.

When you choose OmegaBrand, you’re not just getting hardware; you’re gaining a partner who helps you stay ahead of the latest label printing trends. From expert advice and technical support to fast shipping across North America, our team ensures your labeling setup runs smoothly from day one.

Book a free consultation call with our experts today to discover how OmegaBrand can streamline your labeling workflow, improve efficiency, and set your business up for long-term success.

Final Thoughts

The label printing industry is entering a new era where innovation meets practicality. Once a back-end task, labeling has become a strategic tool that drives trust, efficiency, and customer satisfaction.

The real advantage isn’t just adopting new technology. It’s about aligning those innovations with your long-term business goals. Printers like the SLP-700 Series prove that modern labeling can be smart, fast, and sustainable all at once.

Treat your labeling system as a growth investment, not a routine process. It’s what turns productivity into brand credibility and keeps your business leading, not lagging, in a market that values precision and transparency.

Frequently Asked Questions

What exactly are linerless labels and are they compatible with most printers?

Linerless labels are pressure-sensitive labels without a backing liner, making them more sustainable and cost-efficient. They work best with printers specifically designed for liner-free media, such as the SLP-700 Series, which prevents adhesive buildup and ensures smooth operation.

Is printing eco-friendly media more expensive?

Eco-friendly label materials can cost slightly more upfront, but they often reduce waste and storage costs over time. As sustainable production becomes more common, prices are gradually decreasing, making green labeling both a responsible and financially practical choice.

How do hybrid printers like SLP-700 manage both receipts and labels?

Hybrid printers such as the SLP-700 Series are built with adjustable sensors and print mechanisms that automatically adapt to different media types. They can seamlessly switch between printing receipts and labels without needing separate machines or time-consuming manual adjustments.

Which industries are leading these label printing trends?

Industries like food and beverage, logistics, retail, and healthcare are driving most labeling innovations. Their need for traceability, speed, and regulatory compliance has pushed the adoption of sustainable materials, automation, and smarter label designs across global supply chains.

How can I future-proof my labeling operations?

To stay ahead, invest in scalable label printers that support connectivity, automation, and eco-friendly materials. Regularly review your processes, integrate data-driven labeling, and choose flexible systems that can easily adapt to new regulations and customer expectations.