How Do Barcodes Work? Understanding Their Functionality

11th Aug 2025

TL;DRBarcodes are machine-readable symbols made of black lines and white spaces used to encode product or item data. Scanners read barcodes by detecting light reflection and converting visual patterns into digital information. 1D barcodes (e.g., UPC, Code 128) are utilized in retail, logistics, and inventory management systems for rapid and straightforward data capture. 2D barcodes (e.g., QR codes, Data Matrix) store more data and are used in healthcare, marketing, and high-density tracking. Barcode components include a quiet zone, start/stop characters, data field, and a check digit for accuracy. Barcodes are used everywhere, including retail, hospitals, airports, shipping, manufacturing, and event marketing. Thermal, inkjet, and laser printers can produce barcode labels tailored to your specific volume, material, and resolution needs. Selecting the right barcode system enhances checkout speed, improves inventory control, facilitates traceability, and enhances the overall customer experience. OmegaBrand offers a wide selection of barcode printers, label materials, and expert guidance for your business needs. |

|---|

If you've ever scanned a product at a checkout counter or tracked a shipment online, you've already seen the power of barcodes in action. But how do barcodes work behind the scenes? At their core, a bar code is a machine-readable symbol made up of black lines and white spaces that represents a specific type of data. This simple yet powerful system allows businesses to streamline the checkout process, manage the supply chain, and track products with remarkable accuracy.

By encoding numbers, letters, or symbols into a visual pattern, typically traditional barcodes using 1D lines or 2D blocks, barcodes can be read using optical scanners or modern mobile phones. These devices translate the image of the barcode into digital data, which is then sent to an application or inventory management software to trigger real-time actions like logging a sale, updating stock, or verifying a shipment.

Whether you're managing basic inventory tracking or running a high-volume point of sale system, understanding barcode types is essential for achieving the best price performance and operational efficiency.

What Are Barcodes?

Barcodes are visual data carriers that encode information into a readable format for machines. They help businesses automate tracking, reduce human error, and move goods and services faster.

Let’s take a closer look at how barcode symbols are structured and where you encounter them every day.

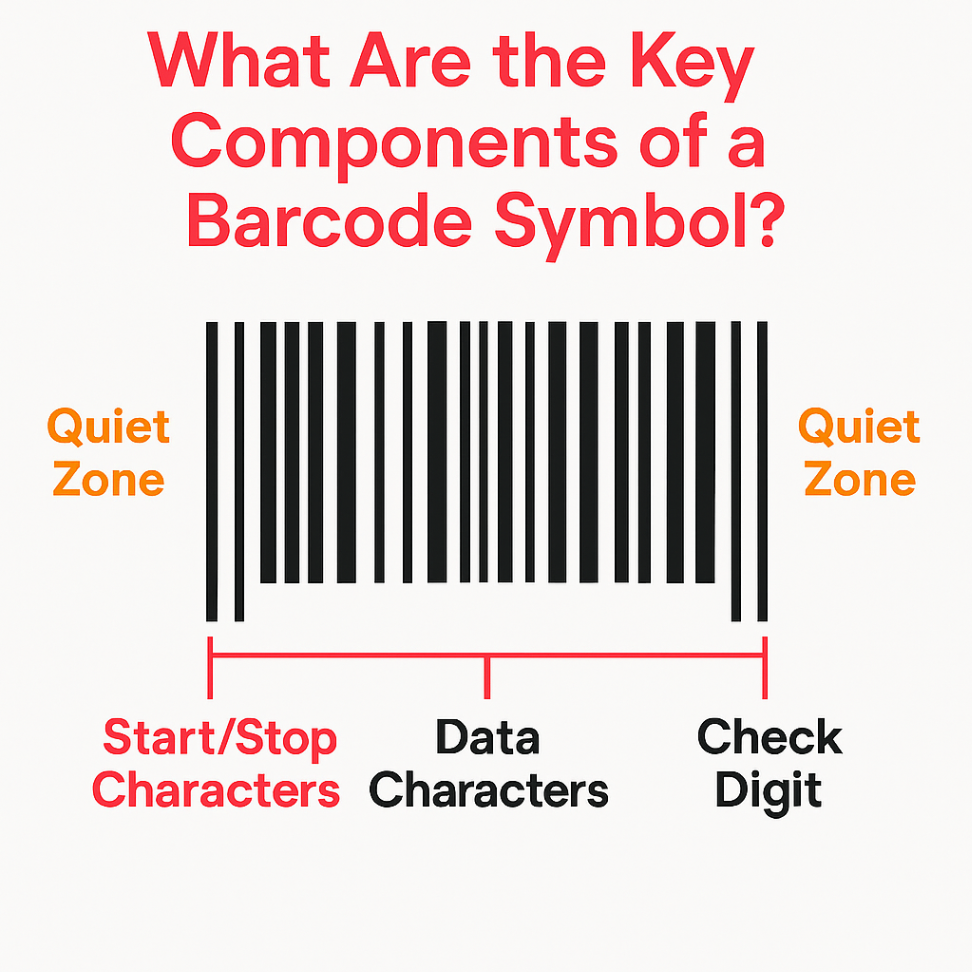

What Are the Key Components of a Barcode Symbol?

Every barcode is built using a specific symbology, which determines how the data is encoded. Common components include:

-

Quiet Zone – A blank margin that helps scanners detect the start and end

-

Start/Stop Characters – Signals that frame the data

-

Data Characters – The core information, like a product ID or serial number

-

Check Digit – A validation character to ensure scan accuracy

Understanding these elements is key to knowing how barcodes work and why precise formatting matters for reliable scans.

Where Are Barcodes Used in Everyday Life?

You’ll find different types of barcodes in places you might not expect:

-

Retail and Grocery Stores – UPC barcodes track products and manage prices

-

Hospitals and Labs – Data Matrix codes label medications and specimens

-

Airports and Logistics – ITF-14 and GS1 barcodes help sort and track packages

-

Events and Marketing – QR codes link printed materials to digital experiences

In every case, the core concept remains the same: barcodes work by translating visual patterns into data that can be quickly scanned, processed, and acted upon.

How Barcodes Work: The Science Behind the Stripes

Ever wondered how a simple pattern of black and white lines can tell a system exactly what product you’re buying? Barcodes work through precise encoding, scanning, and decoding steps that convert visual patterns into usable data in milliseconds.

How Is Data Encoded Using Bars and Spaces?

Barcodes represent data using a combination of bars and spaces, where each variation in width or placement corresponds to a specific digit or character. Different barcode symbologies, like Code 128 or UPC, use unique encoding rules, allowing machines to read everything from simple numbers to full ASCII character sets. The contrast between the dark bars and light spaces forms a pattern that scanners can quickly detect and translate.

What Happens During the Barcode Scanning Process?

When a barcode is scanned, either with a laser scanner or a camera-based system, the device reads the reflected light from the barcode’s surface. This light is interpreted as analog signals, which are then converted into digital data. The scanner identifies the start and stop characters, reads the pattern between them, and sends the output to a connected system (like a POS terminal or inventory app) for immediate processing.

How Is Barcode Data Decoded and Interpreted?

Once the scanner sends the raw data, the software decodes it based on the barcode’s symbology and structure. This decoded information might represent a product identification number, serial code, or batch number, depending on the use case. Additional tools, like check digits or Application Identifiers (AIs) in GS1 barcodes, help ensure accuracy and provide context for how the data should be handled.

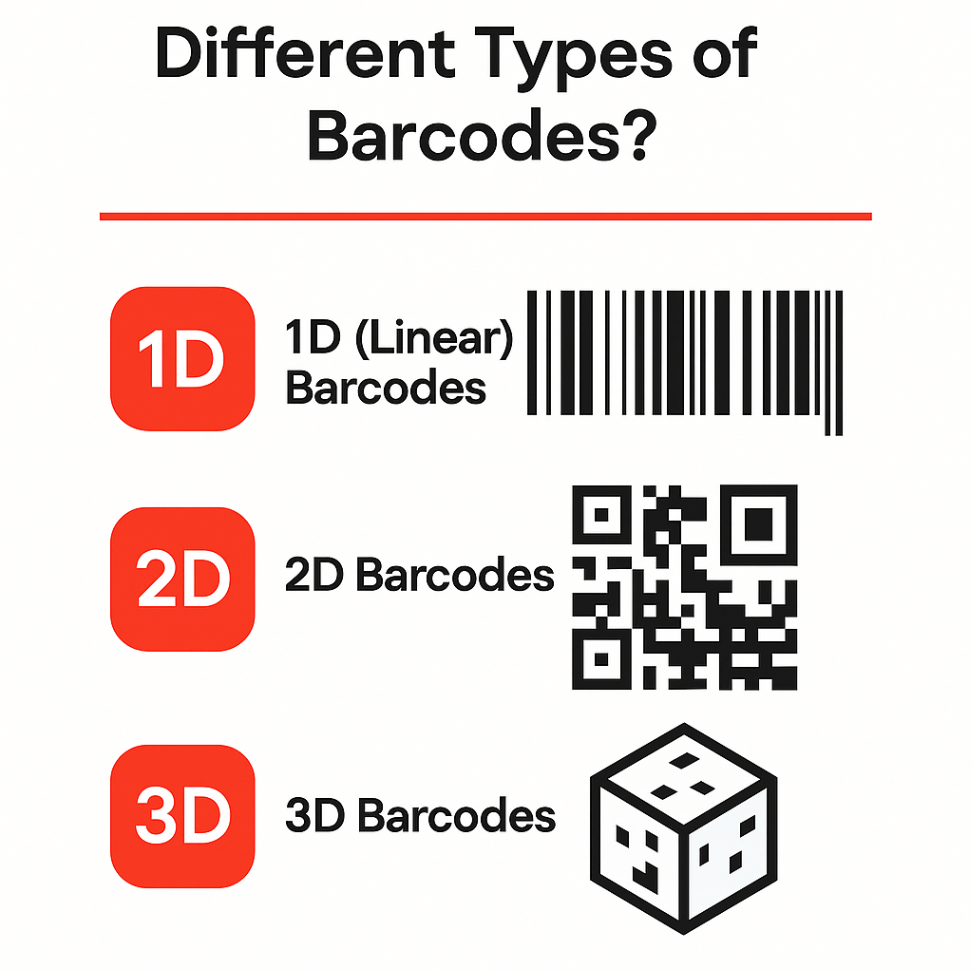

What Are the Different Types of Barcodes?

Not all barcodes are created equal. Depending on how much data you need to encode and how you plan to scan it, you’ll need to choose between various types of barcodes. Let’s break them down by format and function.

What Are 1D (Linear) Barcodes and Where Are They Used?

1D barcodes, also known as linear barcodes, represent data using a series of vertical bars and spaces. They typically encode numeric characters or simple alphanumeric strings, making them ideal for basic applications like product labeling and inventory control.

Common examples include:

-

UPC-A – used in retail and grocery stores in North America

-

EAN-13 – for global product identification

-

Code 128 – found in logistics, shipping, and warehousing

-

ITF-14 – used on outer cartons and packaging

These barcodes are fast to scan but limited in the amount of data they can store.

What Are 2D Barcodes Like QR Codes and Data Matrix?

2D barcodes store data both horizontally and vertically in a grid or matrix pattern. This allows them to hold huge amounts of data, including alphanumeric characters, URLs, images, and special characters.

Key examples include:

-

QR Codes – widely used for marketing, mobile payments, and smart packaging

-

Data Matrix – ideal for medical devices, photo labs, and electronics due to its compact size and high fault tolerance

-

PDF417 – used in government IDs, transportation, and USPS

Unlike 1D barcodes, 2D codes often require camera-based scanners or mobile devices but support error correction and encryption.

Is There Such a Thing as 3D Barcodes?

Technically, 3D barcodes aren’t barcodes in the traditional sense. Instead, they refer to physically embossed or engraved codes, such as those used in aerospace and metal part tracking. These codes are read using laser scanners or 3D imaging systems, not standard barcode readers.

They’re most common in industries requiring permanent marking and high resistance to wear, such as automotive, defense, and industrial manufacturing. While not widely used in commercial applications, they represent the cutting edge of data durability and traceability.

What Are the Main Barcode Symbologies Used in the U.S.?

In the United States, several key barcode symbologies dominate retail, logistics, and industrial applications. Choosing the right one ensures smooth integration with point-of-sale systems, regulatory compliance, and efficient inventory tracking. Let’s explore the most commonly used symbologies across sectors.

What Is UPC (Universal Product Code) and Why Is It So Widely Used?

The UPC (Universal Product Code) is the most recognizable barcode in the U.S., especially in grocery stores and retail environments. It encodes 12 numeric characters and is designed for fast, accurate scanning at checkout.

There are two main versions:

-

UPC-A – standard for most retail products

-

UPC-E – a compressed version used for small items with limited label space

UPC barcodes are regulated by GS1, a global standards organization, and are ideal for manufacturers distributing to North American retailers.

How Are Code 39 and Code 128 Used in U.S. Industries?

Both Code 39 and Code 128 are 1D barcode symbologies widely used in logistics, healthcare, government, and manufacturing.

-

Code 39 supports both alphanumeric characters and is easy to print and decode, making it common in military and industrial labeling.

-

Code 128 offers a higher data density and can encode the full ASCII character set, making it better suited for shipping labels, asset tracking, and high-volume applications.

These barcodes are ideal for encoding serial numbers, identification numbers, and consecutive numbers where more flexibility is required than UPC provides.

What Are EAN Codes and How Do They Compare Internationally?

EAN (European Article Number) barcodes are the international equivalent of UPC and are primarily used outside the U.S., especially in Europe, Asia, and Australia.

-

EAN-13 encodes 13 digits and includes a country code, manufacturer ID, and product code.

-

EAN-8 is a shorter version used for small packaging where space is limited.

Although UPC and EAN codes differ in format, they are often treated as interchangeable in modern retail point-of-sale systems. If your products are sold both in the U.S. and internationally, EAN codes offer better global compatibility.

What Are Barcode Components and Their Functions?

While barcodes might look simple on the surface, each one is built using specific components that ensure it scans accurately and consistently across various environments. Understanding these elements is critical to knowing how barcodes work and optimizing them for printing and scanning systems.

What Are Quiet Zones and Start/Stop Characters?

The quiet zone is the blank margin surrounding a barcode. This space ensures that the scanner can recognize where the barcode starts and ends, preventing false reads. Most barcode symbologies require at least 10 times the width of the narrowest bar as quiet space on each side.

Start and stop characters are special bars that mark the beginning and end of the data. These are essential for orienting the scanner and framing the encoded information, especially in 1D barcode symbologies like Code 128 or Code 39.

How Do Check Digits Help with Error Detection?

A check digit is a mathematically calculated number added at the end of a barcode's data string. It helps confirm that the data has been scanned correctly by validating the barcode's integrity.

For example, UPC barcodes include a check digit based on a weighted calculation of the preceding digits. If the scanner misreads a character, the check digit won’t match the expected result, prompting a re-scan. This built-in error detection feature is crucial in high-volume environments like retail or logistics, where accuracy matters.

Why Is Human-Readable Text Important?

Most barcodes also include human-readable text printed directly below the symbol. This allows employees, warehouse staff, or consumers to manually read the product number, batch ID, or identification number, especially in cases where the barcode is damaged or unreadable by scanners.

While not required in all applications, human-readable characters improve accessibility and act as a backup for visual verification. It's especially helpful in transportation industries, inventory checks, or when generating labels for fresh produce or healthcare products.

Recommended Thermal Printers for Barcodes & Product Labels

Choosing the right thermal printer ensures not only sharp barcode printing but also long-term durability of your labels across different applications, whether you're handling inventory, horticulture tags, apparel care labels, or UPS shipping. Below are OmegaBrand’s top picks for thermal transfer and direct thermal printers to meet a wide range of business needs.

1. TSC TX310-A002-1201 | TX310 300 dpi 4-Inch Wide Thermal Transfer Label Printer For Horticulture Labels

-

Price: $1,128 USD

-

Type: Thermal Transfer | Resolution: 300 dpi | Speed: 6 ips | Print Width: 4"

Built for performance and precision, the TSC TX310 is a robust desktop thermal printer tailored for horticulture tags, plant labels, and industrial product labeling. With 300 dpi resolution and support for thermal transfer media, it prints durable, long-lasting labels that resist fading and moisture.

Key Features:

-

Wi-Fi-ready (with optional module)

-

Ethernet, USB 2.0, USB-A Host, and Serial Interface

-

Horticulture media support

-

Real-Time Clock (RTC) for time-sensitive labeling

2. Bixolon XD3-40DEK 4-Inch Wide 203 dpi - 5 ips Direct Thermal Label Printer | UPS Shipping Label Printer with USB/Ethernet

-

Price: $399 USD

-

Type: Direct Thermal | Resolution: 203 dpi | Speed: 5 ips | Print Width: 4"

Designed specifically for UPS, FedEx, and other shipping workflows, the Bixolon XD3-40DEK is a fast, cost-effective solution for desktop shipping label production.

Best For:

-

E-commerce order fulfillment

-

Courier and logistics services

-

Direct thermal labels (no ribbon required)

-

USB and Ethernet connectivity for easy setup

3. Godex GE300 Desktop Barcode Label Printer

-

Price: $449 USD

-

Type: Thermal Transfer | Resolution: 203 dpi | Speed: 5 ips | Print Width: 4"

Perfect for small to medium-sized businesses, the Godex GE300 balances affordability with high-quality print output for shipping, inventory, and product labeling.

Highlights:

-

USB, Ethernet, and RS232 connections

-

Supports wax, wax/resin, and resin ribbons

-

Compatible with Zebra 110mm x 74m ribbons

-

Compact footprint with 3-year warranty

4. Godex HD830i 8.6” Wide 300 dpi Thermal Transfer Barcode Label Printer

-

Price: $3,595 USD

-

Type: Thermal Transfer | Resolution: 300 dpi | Speed: 4 ips | Print Width: 8.6"

Need large-format barcode or compliance labels? The Godex HD830i is your go-to industrial printer. With its wide 8.6-inch print width, this powerhouse handles bulk pallet labels, hazardous material warnings, and oversized product tags with ease.

Use Cases:

-

Manufacturing and logistics

-

Automotive and compliance labeling

-

Harsh environment labeling (heat, chemicals, abrasion)

Supports:

-

Wax, wax/resin, and resin ribbons

-

Multiple label materials including polyester and synthetic stock

-

3-Year Industry-Leading Warranty

5. Godex RT730iW 4-Inch 300 dpi - 5 ips Apparel Label Maker

-

Price: $1,025 USD

-

Type: Thermal Transfer | Resolution: 300 dpi | Speed: 5 ips | Print Width: 4.16"

The Godex RT730iW is purpose-built for apparel care labels, fabric tags, and textile branding. It includes a care label cutter and external unwinder for seamless, high-volume output.

Specifications:

-

Ribbon Width: 0.79"–4.64"

-

Max Print Length: 30"

-

Ideal for care tags, size labels, and compliance barcodes

-

User-friendly setup and maintenance

Recommended Color Printers for Barcode & Product Labels

Whether you're printing retail packaging, custom stickers, or compliant labels for specialty goods, the following printers deliver premium quality and durability. Here are OmegaBrand’s top recommended color inkjet label printers:

Afinia L502 Color Label Printer

-

Price: $2,795 USD

-

Resolution: 4800 dpi | Speed: 5.2 ips | Print Width: 8"

-

Ink Type: DuraPrime™ Dye Inks (CMYK - Separate Cartridges)

The Afinia L502 is a rugged, industrial-grade printer built for businesses that want full-colour flexibility with sharp barcode reproduction. It prints on a wide range of label materials, from matte paper to glossy polyester.

What makes it stand out:

-

Supports both dye and pigment inks (interchangeable cartridges)

-

Works with glossy, matte, clear, and metallic labels

-

Separate CMYK cartridges reduce ink waste

-

Ideal for cosmetics, food & beverage, and artisan brands

-

Heavy-duty steel construction for durability

Primera LX500 Color Label Printer

-

Price: $1,799 USD

-

Resolution: 4800 dpi | Print Width: 4"

-

Ink Type: Tri-Color Dye Cartridge

Compact yet powerful, the Primera LX500 is ideal for small businesses printing shorter label runs or needing on-demand flexibility. The built-in cutter and high resolution make it perfect for custom labels, stickers, and boutique packaging.

Top features:

-

Print professional-grade labels at home or in-store

-

Works with glossy, matte, and waterproof label stock

-

Built-in cutter for variable sizing

-

Ideal for barcodes, logos, and full-colour graphics

-

Affordable entry into premium colour label printing

-

Price: $3,995 USD

-

Resolution: 1600 dpi | Speed: 8 ips | Print Width: 8.5"

-

Ink Type: Memjet Standard Dye Inks (CMYKK)

VIPColor VP500 Color Label Printer

Designed for high-throughput environments, the VIPColor VP500 is built for businesses needing sharp, full-colour, and high-speed label printing. Its Memjet engine produces vibrant images and barcodes suitable for food products, cannabis packaging, chemical labels, and more.

Why choose it:

-

Ideal for industrial-scale runs

-

Crisp barcode clarity at high resolution

-

Ships with ink combo pack, printhead, and unwinder

-

Optional rewinder for roll-to-roll printing

-

Perfect for GHS labels, health supplements, and premium retail

Recommended Laser Printers for Barcode & Product Labels

If you're looking to elevate your brand presentation with white toner, metallic effects, or waterproof labels, the Afinia LT5C is your best-in-class solution.

Afinia LT5C Laser Color Label Printer With White Toner

-

Price: $13,599 USD

-

Resolution: 1200 dpi | Speed: 6 ips | Print Width: Up to 5"

-

Print Method: Laser (Dry Toner) | Toner Colors: CMYK + White

The Afinia LT5C is a compact yet powerful laser label printer that supports white toner printing, making it ideal for creating premium labels on clear, colored, metallic, and specialty substrates. With professional-grade print quality and exceptional media flexibility, it’s a smart solution for brands seeking high-end, on-demand labels in-house.

Why Choose It:

-

Print on Clear, Black, Metallic & Heat-Sensitive Media

-

Vibrant Full-Color Labels with White Highlights

-

Water-, Scratch- & UV-Resistant Output

-

Fast, Professional Results

-

Simple Setup and Media Loading

Why Professionals Trust OmegaBrand for Barcode Labeling Solutions?

When it comes to barcode printing, precision isn’t optional; it’s essential. That’s why businesses across retail, logistics, manufacturing, and healthcare turn to OmegaBrand.

We don’t just sell printers, we deliver end-to-end barcode solutions tailored to your specific workflow. Whether you need color-rich product labels, durable thermal barcodes, or regulatory-compliant labeling, our carefully curated lineup of printers, ribbons, and software ensures every scan counts.

Not sure where to start?

Our team of experts is just a click away. We'll help you choose the right printer, software, and label stock based on your application, whether you're labeling fresh produce, medical devices, or eCommerce packages.

Conclusion

Whether you’re scanning consumer products at a cash register or tagging parts for the Department of Defense, understanding the types of barcodes, from linear codes like UPCs to advanced 2D formats, is essential for accurate and efficient inventory tracking.

Choosing the right type of barcode and printing method ensures fast transaction speed, minimizes additional human intervention, and captures the relevant information needed for real-time decisions. With tools like CCD scanners and barcode generators, even small businesses can deploy a low-cost, high-accuracy solution for managing product data.

In short, barcodes aren’t just a series of black bars and straight lines; they’re a powerful language that keeps industries running with speed, precision, and accountability.

Frequently Asked Questions:

Who invented barcodes, and when were they first used?

Barcodes were invented in 1949 by Norman Joseph Woodland and Bernard Silver, inspired by Morse code and the incandescent light bulb. The first patent for a barcode system was filed in 1952. Barcodes saw commercial adoption in the late 1970s, with the first scan on a pack of Wrigley gum using a barcode scanner at a retail store.

Can two products have the same barcode?

In most retail and point-of-sale systems, each product requires a unique barcode to track item numbers, prices, and inventory turnover accurately. However, identical products (same size, variant, and brand) may share one barcode. Different items sharing the same code can lead to errors in product information, pricing, and inventory control systems.