Direct Thermal vs Thermal Transfer: What Should You Choose?

23rd Oct 2025

Key Highlights

-

Thermal printing uses heat instead of ink or toner to produce images on labels, tags, and receipts.

-

Direct thermal printing forms images on heat-sensitive paper, ideal for short-term labeling needs.

-

Thermal transfer printing uses a ribbon to create durable images suited for long-term or industrial use.

-

The main difference lies in how each method applies heat and the materials they use to create prints.

-

Direct thermal printers are simple, fast, and low-maintenance, perfect for high-volume, temporary labels.

-

Thermal transfer printers offer superior durability, making them better for outdoor or demanding environments.

-

Hybrid and flex-mode printers allow flexibility when both short-term and durable labels are needed.

-

Choosing the right printing method depends on label lifespan, environmental conditions, and print quality requirements.

Ever had your shipping label fade before the package even arrived? Or watched a barcode become unreadable after a few days in storage? That’s the frustration many businesses face when the wrong printing method is used. It might seem like a small detail, but poor label quality can slow operations, confuse inventory tracking, and cost time and money.

The problem is, not all printing methods are built the same. Some labels are meant to last only a few days, while others must survive months of handling and temperature changes. Choosing the wrong type of printer can lead to wasted supplies, reprints, and fading labels right when you need them most. In fast-moving industries like logistics, retail, or manufacturing, every misprint counts.

That’s where understanding the difference between direct thermal and thermal transfer printing really pays off. In this guide, we’ll break down how each technology works, their pros and cons, when to use them, and why printers like the Seiko SLP-720 can help you cut costs without sacrificing quality. By the end, you’ll know exactly which method fits your labeling needs, and how to make your prints last longer.

What Is Direct Thermal Printing, and How Does It Work?

Think about the receipt you get at a coffee shop or the shipping label on your latest online order, both printed in seconds, sharp and smudge-free, without a drop of ink. That’s the power of direct thermal printing.

This fast, no-fuss technology uses heat to create images directly on coated paper, making it ideal for labels, tags, and receipts that need to be clear, quick, and affordable. It’s a favorite in retail, logistics, and healthcare settings where speed and efficiency matter most.

How It Works

Direct thermal printers use a heated print head that reacts with heat-sensitive paper, known as direct thermal labels, to form images. Here’s what happens during the process:

-

The heated print head makes direct contact with the coated label surface.

-

The heat activates a special chemical layer that darkens where it’s applied, creating the printed image.

-

No ink, toner, or ribbon is required, keeping maintenance and operating costs low.

-

Because the process relies on direct heat, the print quality depends on even temperature distribution and label material consistency.

This simple process delivers sharp, clear results ideal for barcodes, shipping labels, and tags. With fewer moving parts, direct thermal printers stay reliable, require minimal upkeep, and keep operations running smoothly.

What Is Thermal Transfer Printing, and How Does It Work?

Need labels that can handle heat, sunlight, or moisture without fading? That’s where thermal transfer printing excels. It’s built for long-lasting, high-quality labeling in demanding environments.

The printer uses heat to transfer ink from a ribbon onto the label surface, creating crisp, durable images that resist wear and tear. It’s ideal for product tags, barcodes, and industrial or outdoor labeling.

How It Works

Thermal transfer printers use a combination of heat, pressure, and ribbon material to create permanent prints. Here’s how the process works:

-

A heated print head applies controlled heat to a thermal transfer ribbon coated with wax, resin, or a wax-resin blend.

-

The ribbon melts under the heat, transferring ink onto the label surface.

-

The ink bonds firmly with the label material, forming a clear, long-lasting image.

-

Once printed, the ribbon moves forward for the next label, ensuring precise and consistent results.

This process produces labels that resist fading, smudging, and wear. Because the printed image becomes part of the label surface, it stays intact even in demanding environments.

What Are the Main Differences between Direct Thermal Printing and Thermal Transfer Printing?

Both direct thermal and thermal transfer printing use heat to create images, but the way they apply it makes all the difference. Direct thermal printing focuses on speed and simplicity, while thermal transfer printing delivers durable, long-lasting results.

Here’s a quick comparison table highlighting how they differ in materials, maintenance, and performance.

|

Aspect |

Direct Thermal Printing |

Thermal Transfer Printing |

|---|---|---|

|

Printing process |

Uses heat-sensitive paper that reacts directly with the heated print head to form the image. |

Uses a ribbon that melts ink onto the label surface, creating a more durable printed layer. |

|

Materials used |

Works with specially coated paper known as direct thermal labels. |

Uses a thermal transfer ribbon along with various label materials like paper, film, or synthetics. |

|

Durability |

Labels may fade when exposed to heat, light, or friction; best for short-term applications. |

Prints resist fading, moisture, and extreme temperatures; suitable for long-term use. |

|

Maintenance |

Fewer components, simpler design, and lower upkeep. |

Requires ribbon replacement and alignment but offers stable, consistent printing. |

|

Print head life |

Slightly shorter due to direct heat contact with the label surface. |

Longer because the ribbon acts as a buffer between the print head and label. |

|

Use cases |

Ideal for receipts, shipping labels, and temporary tags. |

Commonly used for product identification, inventory tracking, and outdoor or industrial labeling. |

|

Image permanence |

The printed image is created within the label surface. |

The image forms as a separate ink layer bonded to the label. |

Direct thermal and thermal transfer printing each serve distinct needs: one prioritizes simplicity and speed, while the other focuses on durability and long-term readability. Knowing how they differ helps you choose the right approach for your labeling environment and goals.

How Do Direct Thermal and Thermal Transfer Printing Compare? (Side-By-Side Comparison)

Choosing between direct thermal and thermal transfer printing comes down to what you’re labeling, how long it needs to last, and the conditions it will face. Both rely on the same thermal technology but differ in how they create the image and how durable the results are.

Direct Thermal Printing: When Simplicity Shines

Direct thermal printers are all about ease and speed. They don’t use ribbons or ink, which makes them simple to operate and maintain. This approach is perfect for everyday labeling tasks that don’t require long-term durability.

What Makes It Work Well

-

Lower maintenance costs since there are fewer parts and no ink ribbon to replace.

-

An ideal choice for fast, high-volume printing such as receipts, tickets, and shipping labels.

-

Compact and straightforward design that fits easily into tight workspaces.

Where It Might Fall Short

-

Printed images can fade over time, especially with direct sunlight or extreme temperatures.

-

Standard direct thermal labels are sensitive to environmental conditions, which can affect their long shelf life.

-

Limited to black-and-white output, making it less suitable for color branding or detailed graphics.

Thermal Transfer Printing: When Durability Matters

Thermal transfer printers are built for tougher jobs. They create durable labeling that can handle long-term storage, rough handling, or outdoor exposure. This makes them a go-to for industries that need reliability over convenience.

Why It Stands Out

-

Delivers excellent print quality that stays sharp even under harsh environmental conditions.

-

Works with a wide range of label materials, including synthetic ones that resist moisture, chemicals, and abrasion.

-

Thermal transfer printing produces labels ideal for product identification, barcode labels, and industrial applications.

-

Ensures a longer life of the print head, meaning less downtime and consistent output over time.

Points to Keep in Mind

-

Needs a thermal transfer ribbon, which adds a small ongoing cost.

-

Setup takes slightly more effort compared to direct thermal printers.

-

Not the best choice if you only need temporary or short-run labels.

In short, direct thermal printing keeps things simple and efficient, while thermal transfer printing focuses on durability and long-lasting results.

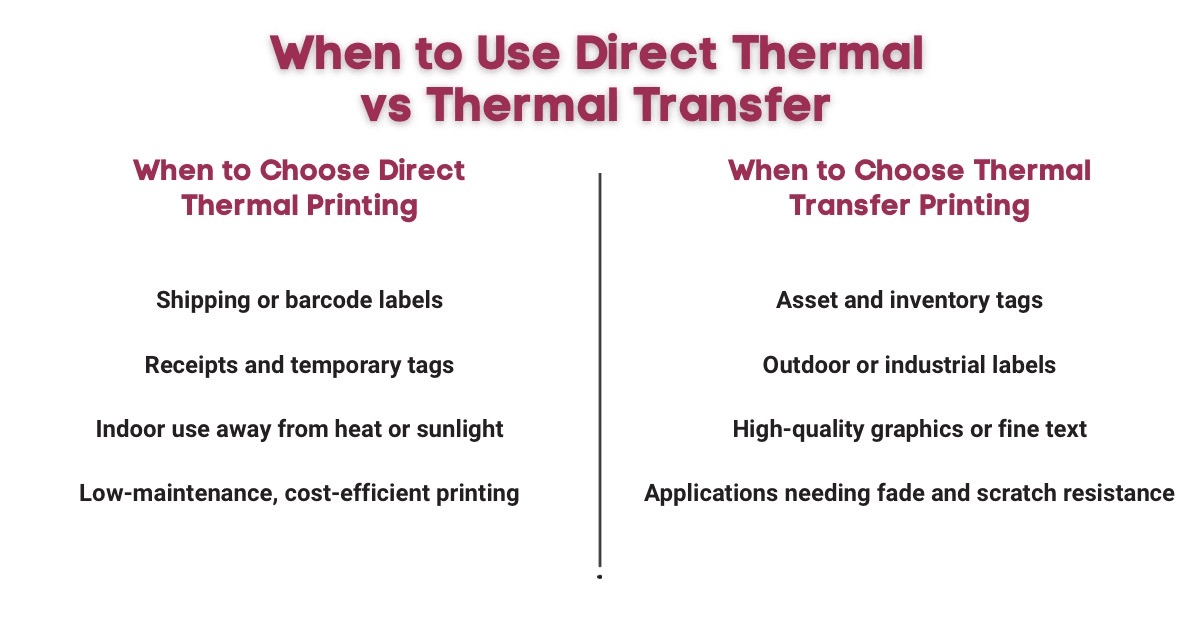

When to Use Direct Thermal vs Thermal Transfer?

Choosing between direct thermal and thermal transfer printing depends on how long your labels need to last, where they’ll be used, and what type of information they need to display. Each method has its strengths, and understanding when to use each one helps you make the most of your label printer.

When to Choose Direct Thermal Printing

Direct thermal printers are the go-to option when you need quick, simple labels for short-term use. Use direct thermal printing when you need:

-

Temporary barcode labels or receipts.

-

Shipping labels that don’t require long-term durability.

-

Tags used indoors or away from heat and light.

-

A solution with lower maintenance costs and minimal supplies to manage.

Since this method uses heat-sensitive material, it’s not designed for extreme temperatures or direct sunlight. However, for short-life applications that prioritize speed and efficiency, direct thermal printing is a reliable and cost-effective choice.

When to Choose Thermal Transfer Printing

Thermal transfer printers are the best option when you need durable labels that can handle wear, time, or tough environmental conditions. This printing method uses a thermal transfer ribbon to bond ink permanently to the label surface, making it more resistant to fading and damage.

Use thermal transfer printing when you need:

-

Labels that must last a long time, such as asset tags or inventory stickers.

-

Outdoor labeling where moisture, friction, or UV exposure are concerns.

-

High-quality graphics or small text that require clear print quality.

-

Labels made from special paper or synthetics that offer added protection.

Thermal transfer technology is the best choice for demanding conditions that require long shelf life and consistent readability. It’s also the preferred method for durable labeling in warehouses, manufacturing, and product identification.

Finding the Right Fit

If your labels are exposed to heat, light, or handling for extended periods, thermal transfer printing is your best solution. For short-term applications that focus on speed and convenience, direct thermal printers handle the job perfectly.

Why SLP-720’s Direct Thermal Mode Is a Cost-Effective Choice?

The Seiko SLP-720 series stands out for one simple reason: it makes everyday label printing smarter and more affordable. Its direct thermal mode eliminates the need for ink, toner, or ribbons, allowing users to print high-quality labels at a lower long-term cost.

1. Fewer Supplies, More Savings

Traditional label printers often rely on ribbons or cartridges that add recurring expenses. With the SLP-720’s direct thermal design, you only need thermal labels. This reduces both supply costs and waste, making it an efficient choice for businesses that print in large quantities. The linerless feature further saves on materials and helps reduce environmental impact.

2. Fast and Reliable Performance

With a print speed of up to 7.87 inches per second and a resolution of 203 dpi, the SLP-720 delivers crisp, clear labels at an impressive pace. The print head is built to last, providing consistent performance with less downtime and minimal maintenance.

3. Designed for Everyday Use

Whether you’re printing shipping labels, barcode tags, or name badges, the SLP-720 handles it with precision. Its compact design fits easily into workstations or checkout counters, while Wi-Fi connectivity offers convenience for both office and small business environments.

4. Long-Term Value

Because the printer uses direct thermal technology, there are no additional components to replace or manage. That means lower maintenance costs, fewer interruptions, and more predictable budgeting over time. It’s a smart investment for teams that need reliable output without ongoing overhead cost.

Hybrid Thermal Printers: When You Need Flexibility Without Compromise

Ever wished one printer could handle both quick shipping labels and long-lasting product tags? That is exactly what a hybrid thermal printer delivers. It gives you the best of both worlds, combining the simplicity of direct thermal printing with the durability of thermal transfer, without needing two separate machines.

How Does a Hybrid Thermal Printer Work?

A hybrid thermal printer is equipped with dual print mechanisms that let you switch seamlessly between direct thermal and thermal transfer modes.

In direct thermal mode, it prints on heat-sensitive labels that are fast and ribbon-free for short-term needs. Switch to thermal transfer mode, and it uses a ribbon to create tough, fade-resistant labels designed to last.

The printer automatically detects which materials are loaded, saving you setup time and ensuring consistent, high-quality results every time.

Why Is Printing Flexibility So Valuable?

Labeling needs can change from one project to the next.

-

Printers for retail stores often need quick-printed shelf or price tags that are replaced frequently.

-

Warehouses need barcodes that stay readable for months or years.

-

Healthcare facilities require both short-term and durable labels for samples, storage, and patient tracking.

A hybrid thermal printer adapts instantly to these varying demands, giving you flexibility without compromising efficiency or print quality.

What Are the Cost and Convenience Advantages?

Running two separate printers means double the supplies, maintenance, and space. A hybrid thermal printer simplifies everything by combining both functions in one system. You will benefit from:

-

Lower ongoing maintenance and supply costs.

-

Less equipment to manage or replace.

-

Quick transitions between print jobs with different durability needs.

Who Should Invest in a Hybrid Thermal Printer?

Hybrid or flex-mode printers are ideal for businesses that need versatility without complexity. If you manage diverse labeling tasks across retail, logistics, healthcare, or manufacturing, a hybrid printer keeps your workflow adaptable, efficient, and cost-effective regardless of the environment or label type.

Why Buy Your Printer and Labels from OmegaBrand?

At OmegaBrand, we go beyond selling printers; we help you build a smoother, more efficient labeling process. From expert advice to dependable supplies, we make sure your printing setup performs at its best.

Here’s why businesses choose us:

-

Complete range of printers, labels, ribbons, and cleaning supplies for any setup.

-

Durable, high-quality label materials that deliver sharp, smudge-free results.

-

LabelJet ribbons engineered for precision and long-lasting performance.

-

Expert guidance from a team that understands your printing challenges.

-

Cost-effective, on-demand solutions that reduce waste and downtime.

-

Trusted compatibility with leading brands like Seiko, Zebra, and Epson.

-

Over 20 years of experience supporting businesses across North America.

Ready to simplify your printing process? Book a free call with our experts and find the right printer, labels, and supplies for your needs.

Choosing Smarter: Your Next Step in Thermal Printing

Understanding the difference between direct thermal and thermal transfer printing helps you pick the right solution for your business. Direct thermal printers offer speed and simplicity for short-term labels, while thermal transfer models deliver long-lasting, high-quality results for tougher conditions.

Before deciding, consider where your labels will be used, how long they must last, and how often you print. For fast, everyday labeling, a direct thermal model like the Seiko SLP-720 is a reliable, cost-effective choice. The right printer not only saves time but also improves accuracy, reduces costs, and keeps your labeling workflow efficient.

Frequently Asked Questions

Does direct thermal print fade faster than thermal transfer?

Yes, direct thermal printing tends to fade faster because it relies on heat-sensitive paper that reacts to light and temperature. Thermal transfer printing, on the other hand, uses ink ribbons that bond to the label surface, making prints more durable and long-lasting.

What ribbons are needed for thermal transfer (wax, wax-resin, resin) and how do they differ?

Thermal transfer printing uses wax, wax-resin, or resin ribbons depending on the application. Wax is ideal for paper labels, wax-resin offers moderate durability, and resin provides the highest resistance against chemicals, moisture, and heat for synthetic labels.

Are there printers that can do both?

Yes, some advanced models are designed to support both direct thermal and thermal transfer printing. These dual-mode printers let users switch easily between methods, offering flexibility for businesses that handle both short-term and long-term labeling needs.

Which method has lower maintenance overhead?

Direct thermal printing generally has lower maintenance overhead. Since it doesn’t use ribbons or ink cartridges, there are fewer components to replace. This makes it simpler, cleaner, and more cost-effective for frequent, short-term printing tasks.