How to Print Barcodes: A Step-by-Step Guide for Beginners

12th Aug 2025

TL;DRBarcodes are widely used across various industries in the U.S., including retail, warehousing, healthcare, manufacturing, and education, for tracking, identification, and automation purposes. Standard barcode formats include UPC-A, Code 128, QR Code, DataMatrix, and ITF-14, each tailored to specific use cases and industry standards. Choosing the correct barcode format depends on your product type, the amount of data that needs to be encoded, the available label space, and the type of scanner used. To generate barcodes, you'll need professional software such as BarTender, Loftware Cloud, NiceLabel, or TEKLYNX, which support various symbologies and database integration. Recommended printers include the Brother TD-4210D for entry-level shipping labels, the Zebra ZD421d for fast, rugged retail use, and the TSC TH320T for high-resolution textile and care label printing. Label materials should be selected based on durability needs. Use paper for indoor, short-term labeling, and polypropylene or polyester for long-lasting, water- or chemical-resistant labels. The barcode printing process involves five steps: determining the barcode type, obtaining or generating the barcode number, designing it using barcode software, selecting the appropriate printer and labels, and finally, testing and printing. While regular inkjet or laser printers can be used, thermal barcode printers are preferred for sharper prints, better durability, and compatibility with label rolls. OmegaBrand offers a full suite of barcode printing solutions, including certified printers, barcode software, and durable label supplies, along with expert guidance to help you print barcodes with speed and accuracy. |

|---|

Printing barcodes may seem complex at first, but once you understand the basics, it’s a straightforward process that can transform your inventory, retail, or manufacturing workflow. Whether you're running a small business, managing a warehouse, or labeling products for retail shelves, knowing how to print barcodes correctly is essential for efficiency, accuracy, and compliance.

In this beginner-friendly guide, we’ll walk you through everything you need to know, from choosing the right barcode type and generating codes to selecting a compatible barcode label printer and label material. You’ll learn how to print barcodes using desktop software, barcode generators, and thermal printers, so you can streamline your operations with confidence.

Let’s break down the process step by step, no jargon, just practical advice that works.

Understanding Barcodes and Their Uses: Why Are Barcodes So Widely Used?

Barcodes aren’t just a convenience; they’re a critical part of business infrastructure across industries. Whether it’s scanning a soda can at checkout or tracking a medical device, barcodes provide a fast and accurate way to manage information associated with physical items.

Where Are Barcodes Used in the United States?

From retail shelves to hospital beds, barcodes are used across nearly every industry in the U.S. Here’s a look at where they appear most frequently, and why learning how to print barcodes properly matters in each context.

1. Retail and Point-of-Sale Systems

The most recognizable use of barcodes is in retail. Products sold in stores are typically labeled with Universal Product Code (UPC) barcodes. These allow for fast scanning at checkout and automatic inventory updates. Whether you're managing a convenience store or an e-commerce fulfillment center, knowing how to print barcodes for retail items is essential for smooth transactions and inventory accuracy.

2. Warehousing and Logistics

Barcodes are crucial in warehousing for tracking stock movement, shelf locations, and shipping details. 1D and 2D barcodes are often printed directly onto shipping labels or product tags to ensure real-time traceability throughout the supply chain. For warehouse managers, understanding how to print barcodes for pallets, cases, or individual SKUs helps improve speed, accuracy, and order fulfillment rates.

3. Healthcare and Pharmaceuticals

In hospitals and pharmacies, barcodes are used for patient identification bracelets, tracking medications, and lab samples. This not only prevents medical errors but also improves compliance with FDA and HIPAA standards. Medical staff often use portable barcode printers to label items at the point of care, which is another key reason to learn how to print barcodes on demand.

4. Manufacturing and Asset Tracking

U.S. manufacturers rely on barcodes to identify raw materials, monitor production lines, and track finished goods. Asset tags with Code 39 or Data Matrix barcodes are commonly printed using thermal transfer printers for durability in industrial environments.

5. Government and Education

Public sector organizations and schools use barcodes for ID badges, equipment tracking, and library systems. With simple label design software and the right printer, even non-technical users can learn how to print barcodes that meet internal recordkeeping and audit requirements.

How Do You Choose the Right Barcode Format?

Choosing the right barcode format is a crucial first step before you even begin thinking about how to print barcodes. Not all barcodes are created equal; some are designed for small packages, while others are designed for industrial applications. The right format depends on your product type, the amount of data you need to encode, and how the barcode will be scanned.

Let’s break down the key factors that will help you choose the correct barcode type for your business.

1. Type of Product and Industry Standards

Every industry tends to rely on specific barcode formats that adhere to global standards and retail compliance.

-

Retail products in the U.S. use UPC-A or UPC-E barcodes for universal compatibility with point-of-sale systems.

-

Pharmaceuticals and medical devices may require GS1 DataMatrix codes for serialization and regulatory tracking.

-

Shipping and logistics commonly use Code 128 or ITF-14 for labeling at the case and pallet levels.

Before deciding how to print barcodes, confirm whether your industry follows a required standard. Using the incorrect format can result in scanning errors or non-compliance with retailers or government bodies.

2. Data Capacity Requirements

Some barcodes only hold a handful of digits, while others can store hundreds of characters.

-

1D barcodes like UPC and Code 39 are great for basic IDs, SKUs, and short numeric or alphanumeric codes.

-

2D barcodes like QR Codes and DataMatrix can hold larger amounts of data, such as URLs, expiration dates, or serial numbers.

If you’re encoding complex data, you'll need to choose a format with greater capacity and clarity. And remember, as data increases, the barcode size may increase, affecting how to print barcodes clearly without distortion.

3. Printing Space and Label Size

Limited label real estate? Your barcode format must fit within the available space without compromising scannability.

-

UPC-E and DataMatrix codes are ideal for small items like cosmetics or electronics.

-

Large-format codes, such as ITF-14 or Code 128, work better on cartons, outer boxes, or shipping labels.

The more compact the barcode, the more critical it becomes to use a high-resolution printer. If you're learning how to print barcodes for small labels, ensure your print method (thermal transfer or laser) can maintain crisp, readable lines.

4. Scanning Environment and Equipment

Where and how a barcode is scanned can influence your format selection.

-

Retail POS scanners are optimized for 1D linear barcodes.

-

Warehouse scanners or mobile data terminals often support both 1D and 2D formats for versatility.

-

Outdoor or industrial settings may require larger, high-contrast barcodes that resist abrasion or poor lighting conditions.

Before printing, test your barcode design with the actual scanning devices your staff or partners will use. The scanning environment should be considered when selecting both the barcode format and the material used, especially if you're printing on thermal labels that will be exposed to heat, cold, or moisture.

What Tools and Software Do You Need To Print Barcodes?

Knowing how to print barcodes starts with having the right tools in place. It’s not just about choosing any printer and hitting ‘print.’ Barcode printing requires specific software, compatible hardware, and label materials that ensure your barcodes are sharp, scannable, and compliant with industry standards.

Here’s a breakdown of what you’ll need to get started.

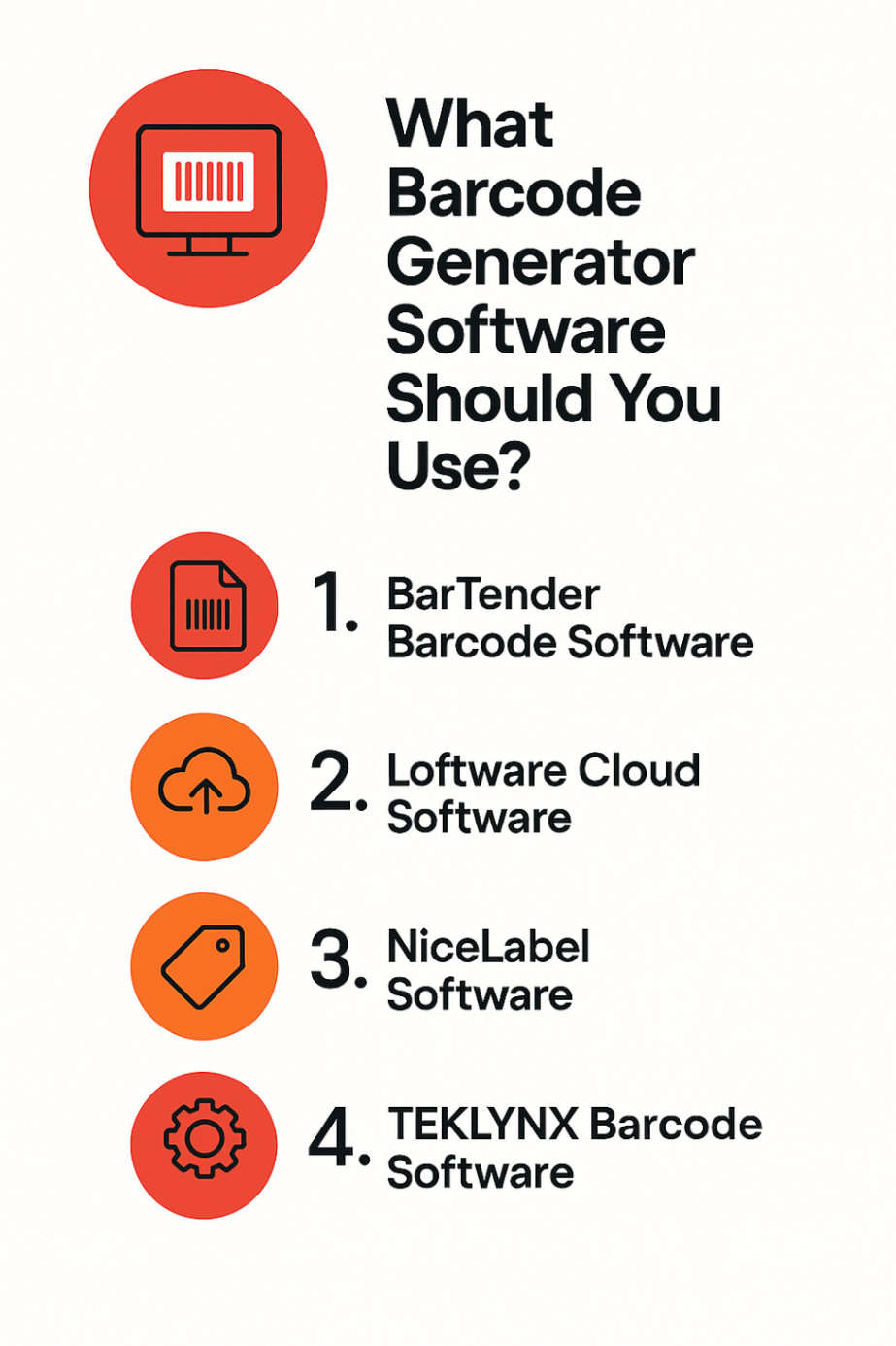

What Barcode Generator Software Should You Use?

To generate accurate, standards-compliant barcodes, you'll need professional barcode design software that can handle various symbologies (like UPC, Code 128, QR Codes) and integrate with your database or POS system.

At OmegaBrand, we offer a full range of industry-trusted barcode software solutions:

1. BarTender Barcode Software

One of the most popular choices for both enterprise and small business users. BarTender supports over 400 barcode types, advanced label design, and integration with ERP systems.

-

Ideal for: Manufacturing, retail, logistics

-

Available in Starter, Professional, Automation, and Enterprise editions

-

Supports database connectivity and automation

2. Loftware Cloud Software

Loftware's cloud-based solution offers centralized label management and design across distributed teams. Ideal for multi-location operations and industries with stringent compliance requirements.

-

Ideal for: Regulated industries, distributed teams

-

No software installation needed, design and print from any browser

-

Scalable for enterprise use

3. NiceLabel Software

NiceLabel desktop software is ideal for businesses that need powerful on-premise solutions. It combines label design tools with print automation and version control.

-

Ideal for: Mid-size businesses, industrial use

-

Supports all major barcode types

-

Integrates with Excel, SQL databases, and ERP systems

4. TEKLYNX Barcode Software

With over 160 SKUs, TEKLYNX offers a versatile suite of label design tools from entry-level to enterprise-grade. It supports global standards like GS1, GHS, and UDI.

-

Ideal for: Healthcare, manufacturing, food & beverage

-

Products include LABELVIEW, CODESOFT, and SENTINEL

-

Powerful automation and compliance features

Browse all barcode software here: https://www.omegabrand.com/barcode-software/

What are the Best Compatible Printers and Label Materials?

Once you’ve designed your barcode, the next step in how to print barcodes is selecting the right printer and label material.

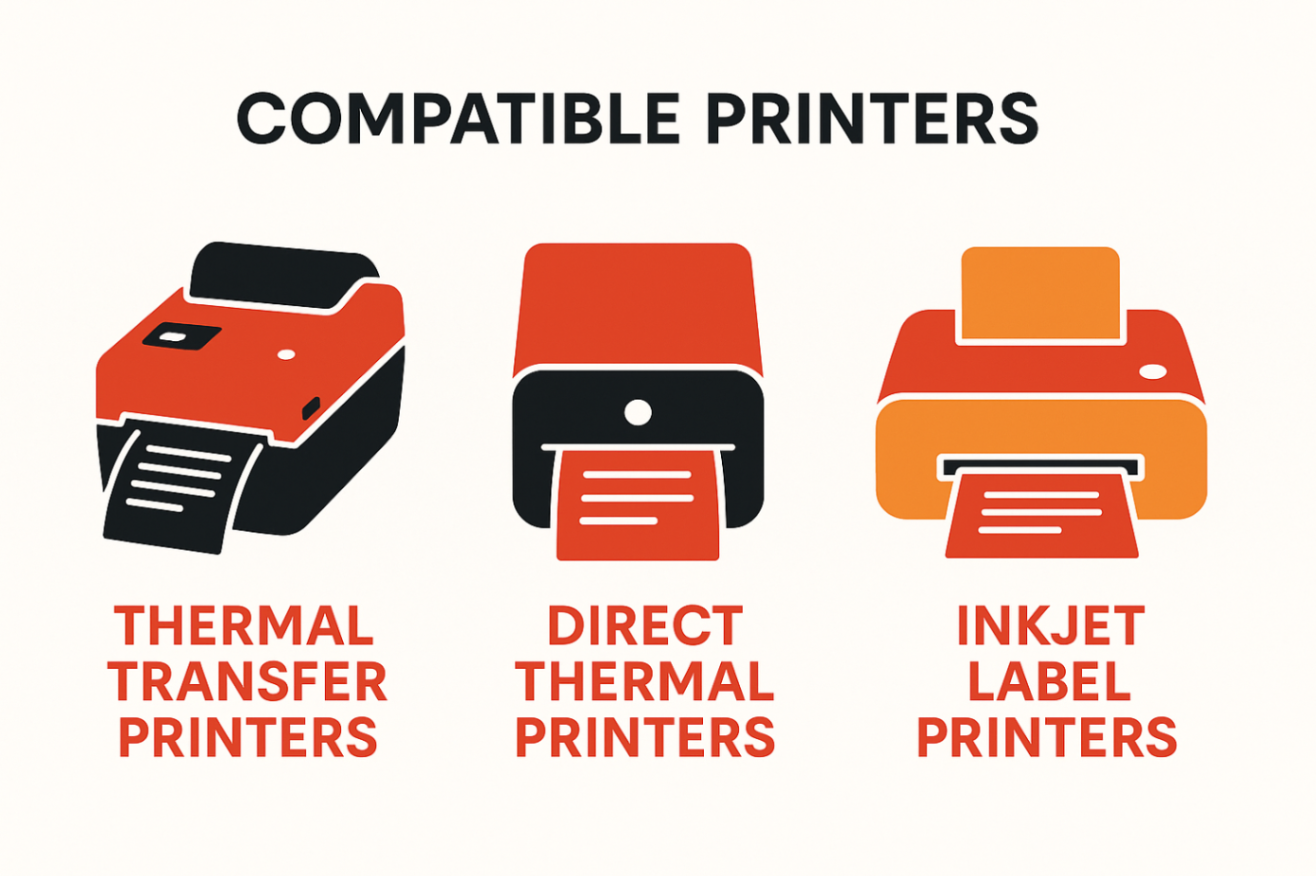

Compatible Printers

-

Thermal Transfer Printers – Best for long-lasting labels in industrial, healthcare, and outdoor settings. Use with ribbon and label stock.

-

Direct Thermal Printers – Ideal for short-term labels, such as shipping or receipts. No ribbon needed, but labels may fade over time.

-

Inkjet Label Printers – Useful for full-color barcode labels, especially for branded packaging.

Make sure your printer resolution is at least 203 dpi (dots per inch) for scannable barcodes. Higher resolutions like 300 dpi are recommended for smaller labels or 2D codes.

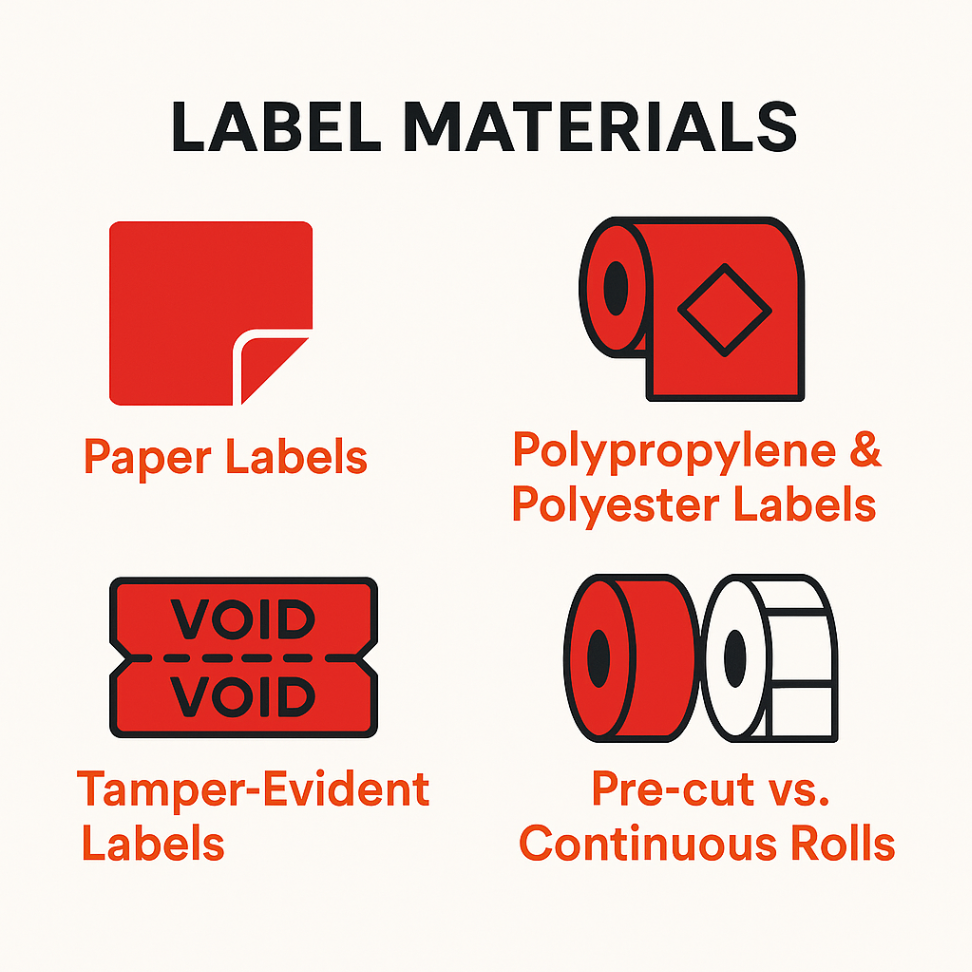

Label Materials

Choosing the correct label material ensures your barcode remains readable throughout its lifecycle:

-

Paper Labels – Cost-effective for indoor use and short shelf-life products

-

Polypropylene & Polyester Labels – Durable, waterproof, and chemical-resistant, ideal for harsh environments

-

Tamper-Evident Labels – For security-sensitive items like pharmaceuticals or electronics

-

Pre-cut vs. Continuous Rolls – Choose based on your printer model and desired label size

Tip: Always match the label material and ribbon type (if using thermal transfer) to ensure proper adhesion, durability, and print clarity.

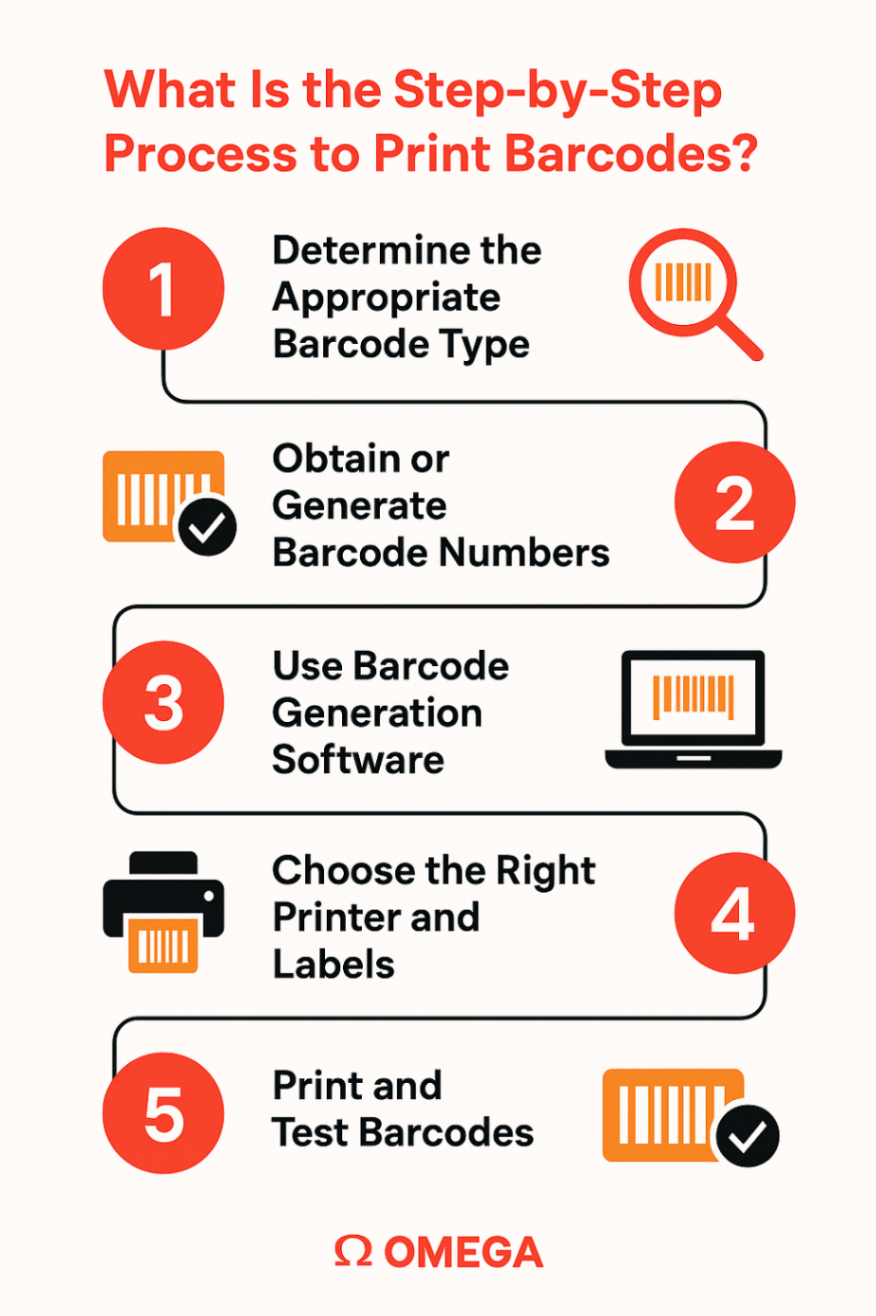

What Is the Step-by-Step Process to Print Barcodes?

Learning how to print barcodes may seem daunting at first, but with the right tools and a clear process, it becomes a straightforward task. Whether you're labeling retail products, shipping packages, or tracking inventory, following a structured workflow ensures that your barcodes are accurate, scannable, and compliant with industry standards.

1. Determine the Appropriate Barcode Type

Before you start designing or printing anything, identify the barcode symbology that fits your use case.

-

UPC-A or UPC-E: Standard for retail products in the U.S.

-

Code 128: Common in shipping and logistics

-

QR Code or DataMatrix: Great for 2D barcodes with embedded data or URLs

-

EAN-13: For international retail use

-

ITF-14: Used for outer cartons and bulk packaging

Your barcode type will depend on what you're labeling, how it’s scanned, and where it’s sold or shipped. This decision impacts both your software setup and how you’ll print the barcodes later.

2. Obtain or Generate Barcode Numbers

You can’t create a barcode without a valid number behind it. Depending on your industry, you’ll either:

-

Register with GS1 to obtain unique Global Trade Item Numbers (GTINs) for retail products

-

Use internal SKU or serial number systems for warehouse, manufacturing, or asset tracking

-

Create encoded data for QR codes or 2D formats (e.g., URLs, batch numbers)

Avoid randomly assigning numbers for retail items; major retailers and marketplaces require GS1-compliant codes to avoid duplication and rejection.

3. Use Barcode Generation Software

Once you have your barcode numbers, it’s time to generate the visual barcode using software. You can download powerful barcode tools like:

Choose from powerful barcode tools like:

-

BarTender – Ideal for all barcode types and label automation

-

Loftware Cloud / NiceLabel – Browser-based design with database integration

-

TEKLYNX – Ideal for regulated industries and bulk printing

These programs allow you to:

-

Design barcode labels

-

Select barcode type (e.g., UPC, Code 39, QR)

-

Connect to a database (for bulk or dynamic printing)

-

Preview and export printable label files

Proper software ensures that the barcode is encoded correctly and adheres to required print specs and industry standards.

4. Choose the Right Printer and Labels

Now that your barcode design is ready, you’ll need compatible hardware and label stock to print clean, scannable barcodes.

Printers:

-

Thermal Transfer Printers – Ideal for long-lasting, industrial labels

-

Direct Thermal Printers – Perfect for shipping and short-term labeling

-

Inkjet/Color Printers – Best for custom product packaging with visual branding

Ensure your printer supports at least 203 dpi resolution, higher for small or high-density barcodes.

Labels:

-

Paper Labels – Low cost, ideal for dry indoor use

-

Polypropylene/Polyester – Durable, water/chemical-resistant

-

Adhesive type – Permanent, removable, or tamper-evident

Label size also matters; ensure the barcode fits with enough white space (quiet zone) around it for clean scanning.

5. Print and Test Barcodes

Once everything’s in place, it’s time to print. Start with a test batch to ensure:

-

Clarity – No smudges, fading, or streaking

-

Proper spacing – Barcode is centered and has adequate margins

-

Scan reliability – Test with a barcode scanner or mobile app

Run your barcodes through the same scanners your team or retail partners will use. Poorly printed or misaligned barcodes can lead to stock issues, checkout delays, or compliance failures.

What Are the Recommended Printers for Printing Barcodes from OmegaBrand?

When you're serious about how to print barcodes accurately and efficiently, your printer choice matters. Whether you need crisp retail labels, fast shipping tags, or durable textile care labels, OmegaBrand offers reliable, high-performance desktop barcode printers built for diverse business needs.

Let’s take a closer look at three standout models:

1. Brother TD-4210D 4.3" | 203 dpi | 5 ips Direct Thermal Desktop Shipping Label Printer with USB

The Brother TD-4210D is a dependable direct thermal printer designed for shipping labels, barcode tags, and shelf stickers, all without the need for ink or ribbons. Compact yet capable, it offers 203 dpi resolution and a 5 ips print speed, making it ideal for retail, logistics, and warehouse environments that require simple, high-volume barcode printing.

Key Specs:

-

Print Width: Up to 4.3 inches

-

Print Method: Direct Thermal

-

Print Speed: 5 inches per second

-

Resolution: 203 dpi

-

Connectivity: USB / Serial

-

Media Compatibility: Supports all direct thermal rolls up to 5" OD

-

Price: $470.00

Why Choose It?

If you're just starting out and want a durable, affordable barcode printer that integrates seamlessly into existing systems, this is a perfect entry-level solution. It handles everyday barcode printing tasks with speed and precision.

2. Zebra ZD421d 4-Inch 203 dpi, 6 ips Direct Thermal Desktop Label Printer

The Zebra ZD421d takes things up a notch with faster speeds and modular connectivity options. Known for its rugged construction and user-friendly interface, this printer delivers consistent performance even in demanding environments. It's ideal for printing shipping labels, retail product stickers, or inventory tags.

Key Specs:

-

Print Width: Up to 4 inches

-

Print Method: Direct Thermal

-

Print Speed: 6 inches per second

-

Resolution: 203 dpi

-

Connectivity: USB, USB Host, BTLE5 (Bluetooth Low Energy)

-

Memory: 256MB SDRAM / 512MB Flash

-

Price: $490.00 (MSRP: $725.11)

Why Choose It?

Its quick setup, intuitive design, and modular connectivity slot make the ZD421d a great choice for businesses that need scalable barcode printing. Additionally, Zebra's reputation for durability ensures that this printer will withstand heavy workloads without compromising print quality.

3. TSC TH320T 2-Inch 300 dpi, 6 ips Textile Label Maker

If you need to print textile care labels, fabric tags, or high-density barcodes, the TSC TH320T is a specialized thermal transfer printer built for precision. With 300 dpi high-resolution printing and a 6 ips print speed, it ensures that even the smallest text or barcode remains sharp and scannable.

This Care Label Printer Kit includes:

-

TSC TH320-A001-0001: 2" thermal transfer printer

-

TSC CUT-TH220-0002: Automatic care label cutter

-

TSC OP-COM-0002: External label unwinder (supports 3" core, 8" OD rolls)

Key Specs:

-

Print Width: Up to 2 inches

-

Print Method: Thermal Transfer

-

Print Speed: 6 inches per second

-

Resolution: 300 dpi

-

Price: $1,240.00

Why Choose It?

The TH320T is purpose-built for textile and apparel manufacturers needing durable, wash-proof labels. With the included cutter and unwinder, this all-in-one kit streamlines the printing process, perfect for compliance-focused garment tagging.

Take the Guesswork Out of Barcode Printing with OmegaBrand

If you're serious about how to print barcodes correctly, every time, OmegaBrand has you covered. We’re not just a product catalog; we’re your barcode printing partner. Here is why Professionals Trust OmegaBrand:

-

Premium Barcode Printers from Zebra, Brother, TSC & more

-

Certified Barcode Software for every industry, retail, logistics, healthcare, and manufacturing

-

High-Quality Labels & Ribbons built for durability and scannability

-

Expert Support to help you choose the right tools for your workflow

Whether you're printing 10 labels a day or 10,000, we’ll help you build a barcode system that’s fast, accurate, and future-proof.

Print with precision. Scale with confidence. Partner with OmegaBrand.

Conclusion

Learning how to print barcodes doesn’t have to be overwhelming. With the right barcode type, quality label software, compatible printer, and a few best practices, you can streamline your operations and maintain inventory accuracy with ease. Whether you're printing for retail, logistics, or manufacturing, this guide equips you with the knowledge to get started confidently.

Frequently Asked Questions:

Can I print barcodes using a regular home printer?

Yes, you can print barcodes using a standard inkjet or laser printer, provided the resolution is high enough (preferably 300 dpi). However, for long-term durability and scannability, especially on product labels, thermal barcode printers are recommended for cleaner lines, better contrast, and compatibility with label rolls.

What is the best software to generate barcodes?

Popular barcode software includes BarTender, Loftware Cloud, NiceLabel, and TEKLYNX, offering robust design tools, database integration, and compliance with global standards. The best choice depends on your industry, print volume, and integration needs. These programs ensure your barcodes are scannable, accurate, and standards-compliant.

Can I create barcodes in Microsoft Word or Excel?

Yes, you can create barcodes in Word or Excel using barcode fonts or add-ins. However, this method has limitations in formatting and encoding. For reliable results, especially in business environments, it's better to use dedicated barcode software that supports advanced symbologies and generates printer-ready barcode graphics.